This is not Buzz Aldrin’s space chow

Michele Perchonok sat contemplating a shrink-wrapped brick of freeze-dried mac and cheese just outside the test kitchen at NASA’s Johnson Space Center.

The dish has been served countless times on the space shuttle and International Space Station. When astronauts are so far from home, this is the comfort food they crave.

But this particular entree won’t be on the menu when astronauts blast off for Mars, scheduled for some time about 2030. The see-through package isn’t impervious to moisture and oxygen, so the pasta could spoil before it can be eaten. Simple alternatives, like foil packages, are out of the question: They are too heavy.

“We’d like to have that solved by 2015 or 2016,” said Perchonok, NASA’s manager of advanced food technology.

It’s just one of many issues her staff of 15 food lab scientists must ponder as they come up with a menu that’s light enough, nutritious enough, tasty enough and durable enough to withstand a years-long mission to the Red Planet.

There are plenty of technological hurdles NASA must overcome before it sends humans into interplanetary space. Aeronautical engineers will have to control the Ares 1 launch vehicle’s tendency to shake violently during liftoff. Usability experts must design more nimble spacesuits. Materials scientists will need to develop a substance to absorb the intense heat the Orion crew vehicle will generate as it barrels through Earth’s atmosphere at 25,000 mph.

The food technology team’s task may not be rocket science, but it is daunting in its own way, and just as crucial to the mission’s success.

Imagine having to pack more than 6,570 breakfasts, lunches, snacks and dinners all at once -- enough meals to feed six people every day for more than three years. Imagine preparing all these meals with an allotment of 3.2 pounds of food per person per day, about one-third less than the average American eats each day on Earth. Imagine that each dish needs to have a five-year shelf life. And imagine having to transport all the meals to a dining table 55 million miles away, where cooking equipment will be rudimentary at best.

Perchonok betrays no hint of panic. Designing a menu for Mars is simply a scientific problem to be solved like any other.

“We will get there, because we won’t fly if we can’t do it, and I don’t want to be the person responsible for that,” she said.

Think astronaut food and you’re likely to conjure up images of freeze-dried ice cream or Tang (which was invented by General Mills Corp., not NASA).

The first American forays into space weren’t long enough to bother with food. When flights got longer, early astronauts were treated to a delicacy originally developed for pilots of U2 spy planes.

“It was like a toothpaste container with a vegetable puree -- jar baby food, basically,” said Paul Lachance, a retired Rutgers University professor of nutrition and food science who worked on NASA’s astronaut feeding program in the 1960s.

Some of the scientific questions on the early flights were basic. “Would stuff float, or go down the wrong tube?” Lachance said. “They wanted to see that you didn’t choke.”

By the time of the Apollo missions, meals resembled actual food: dehydrated sausage patties and fruit cocktail for breakfast, say, and spaghetti with meat sauce for dinner.

Today, space cuisine is more sophisticated. Favorite dishes on shuttle and space station missions include freeze-dried shrimp cocktail, irradiated beef fajitas and shelf-stable cherry-blueberry cobbler.

Yet some mundane foods remain beyond the reach of NASA’s kitchen wizards. They can’t concoct a zero-gravity pizza because the crust would need to be preserved differently than the toppings. Nor can they make a cheesecake that survives the preservation process without hardening.

Tastiness is a high priority, but food safety is the paramount concern for astronauts beyond the reach of advanced medical care.

NASA has multiple strategies for keeping food edible for up to two years, as required for the space station.

Cooked items are placed in a flexible foil-and-laminate package and thermostabilized in an industrial pressure cooker. Heat from the process destroys microorganisms and makes the package shelf-stable, like canned food.

Irradiation is used to make meat dishes safe to store at room temperature for up to two years.

Freeze-drying food deprives bacteria and other bugs the water they need to multiply. That type of food works well on the shuttle because the spacecraft’s fuel cells produce water as a byproduct. But water will be in short supply on Mars, making that technology much less practical.

And the food to be sent to Mars will need a much longer shelf life.

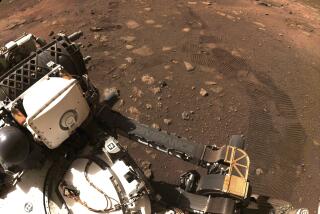

It will take at least six to eight months to fly there when Earth and Mars are at their closest, and astronauts would probably sojourn on the Red Planet for a year and a half so that they can head home when the planets are once again close by. If NASA decides to send food ahead of time in a separate capsule, the meals will have to last five years.

Some items from the space station menu might remain safe to eat for that long. But none are likely to remain appetizing.

The Maillard reaction, a chemical interaction between amino acids and sugars, turns foods brown, even inside a can or other package. Or a small amount of air can trigger oxidation, which turns food rancid and degrades vitamins and minerals. If any water gets into a meal pouch, it can boost microbiological activity and alter the food’s color, flavor and texture.

“There’s going to be chemistry in there,” Perchonok said.

To slow the inevitable chemical reactions, NASA is seeking gentler technologies that kill pathogens with less heat so the food takes longer to degrade. One leading candidate is a sterilization process that relies more on pressure than temperature.

After food is sealed in a pouch, it is heated to a mild 250 degrees for about three minutes. Then the pouch is placed in a drum, which is then filled with water to induce 100,000 pounds per square inch of pressure for about five minutes -- just long enough to crush the cells of any dangerous microbes lurking inside.

It took nine years for a group of government, academic and industrial researchers to make this water-pressure system effective for low-acid foods, which are particularly hospitable to certain kinds of pathogens. The Food and Drug Administration ruled in February that the Army could use the process to make home-style mashed potatoes with a shelf life of at least three years. The potatoes are ready to eat as soon as the package is opened.

“Now that we’ve got that system down, we can look for other products where we can do the same thing,” said Stephen Moody, who leads development of individual combat rations at the U.S. Army Natick Soldier Research Development and Engineering Center in Massachusetts and often shares expertise with NASA.

Another promising technology combines microwave radiation with heat from water to sterilize food pouches in five to eight minutes instead of the usual 40 to 60. Food tastes fresher and lasts longer because it is subjected to high heat for much less time.

Scientists at Natick and Washington State University have used the method to create another version of mashed potatoes, which the FDA is reviewing. They’re working on macaroni and cheese and chicken and dumplings.

These technologies require new packaging materials that don’t fray under high pressure. Foil pouches are no good in microwave sterilizers, are heavy to lift into space and will leave ash behind if they are incinerated on the Martian surface. But whatever the team comes up with will have to protect food from air and water just as effectively.

Tom Oziomek, the packaging scientist in Perchonok’s group, is testing a new type of polyethylene material coated in aluminum-oxide nanoparticles that was developed for use in the pharmaceutical industry. The aluminum oxide layer has many of the same useful barrier properties as foil.

The high-tech plastic can protect food for up to 18 months -- sufficient for a lunar excursion, perhaps, but not a trip to Mars.

“This material is probably 80% there,” Oziomek said.

It’s not yet clear whether astronauts on Mars will use a shuttle-style galley, where meals are prepared by adding cold water, adding hot water, or heating in a makeshift oven. A simple bread maker might be included, or a multipurpose device that could turn soybeans into oil or tofu and transform wheat into pasta and breakfast cereal, Perchonok said.

Only after the right preservation and packaging technologies are found can the food scientists get down to the business of recalibrating old recipes and creating new ones. Their lab resembles a home economics classroom, except that it is outfitted with specialized equipment like a vacuum moisture analyzer, a pH meter, a colorimeter, a texture analyzer, a viscometer and a huge shelf-life testing chamber. Perchonok said she anticipated that recipe reformulation would begin in 2013.

In the meantime, scientists are weighing the pros and cons of supplementing packaged meals with fresh fruits and vegetables. NASA first grew plants in space in the 1960s, and a team at Kennedy Space Center in Florida has been developing a domed chamber in which astronauts could raise crops like lettuce, tomatoes, carrots and green onions hydroponically.

“That would really add to the quality of life and acceptability of the diet,” said Ray Wheeler, the plant physiologist in charge of the project.

Perchonok acknowledged her team might fall short of some of its goals. But this being NASA, there’s always a Plan B.

If there’s just no way to eliminate the need for heavy foil pouches, for instance, the team will stress their versatility to mission planners -- as bags to store Martian soil samples, Perchonok said.

“Or,” she added, “dirty laundry.”

More to Read

Start your day right

Sign up for Essential California for news, features and recommendations from the L.A. Times and beyond in your inbox six days a week.

You may occasionally receive promotional content from the Los Angeles Times.