A 3-D-printed airway splint cures babies, then disappears

At the University of Michigan, printers spit out problem sets and term papers. Now there’s one that makes biodegradable medical devices, allowing babies with a potentially fatal condition to grow up and live a normal life.

The new device is called an airway splint. It’s designed to support the tiny airways near the lungs that are prone to collapse in patients with tracheobronchomalacia.

So far, the medical implant has been tested in three children between the ages of 3 months and 16 months. Before getting the implant, the young patients had spent much of their lives in intensive care, where they needed to be on ventilators full-time to help them breathe.

But after surgeons inserted the small white device around their narrow airways, all three recovered rapidly, according to a study published this week in the journal Science Translational Medicine.

“Holidays are no longer spent in the hospital, the kids are no longer sedated and paralyzed,” said Dr. Glenn Green, a pediatric otolaryngologist at the university’s C.S. Mott Children’s Hospital in Ann Arbor, Mich., and one of the senior authors of the study.

In the past few years, 3-D printers have expanded the possibilities for doctors and their patients. With customized blueprints and the right mix of ingredients, the printers can make prosthetic hands, ears and even samples of livers, kidneys and other tissues.

But the airway splint is the first 3D implant made for kids and designed to grow along with the patient.

“We used laser light to transform dust into a medical device that changes how the body develops,” Green said. “It would have been inconceivable when I was a resident” in the 1990s.

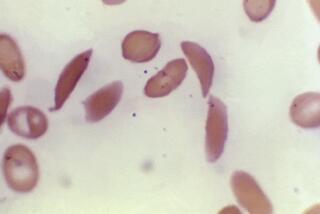

Each roughly inch-long device looks like a small, ridged tube with gaps like a picket fence and an opening that runs along the bottom. It is made of polycaprolactone, a type of polyester that safely disintegrates in the body after three years, give or take six months.

The cuff-like device goes outside the collapsed part of the child’s airway, which is as slim as the lead inside a pencil. During surgery, tiny sutures attach it to the walls of the compromised airway.

To create the individual splints, the researchers used CT scans to make a three-dimensional digital model of the patient’s collapsed airways. Then a computer program designed the splint based on the patient’s specific anatomy.

Before printing the device, the researchers fit the virtual splint onto the patient’s virtual airway to test how well the splint would work in the present as well as in the future.

“The device is designed to have flexibility as the airways grow,” said Scott Hollister, a biomedical engineer at the University of Michigan who designed the device. As the airway gets bigger, the splint stretches out. Over time, it degrades until it is ultimately absorbed by the body, like biodegradable stitches, he said.

To help visualize the way it works, try grasping your left wrist with your right hand. Now imagine your left wrist growing thicker. As it does, the tips of the fingers on your right hand are pulled away from your thumb. The same thing happens with the splint.

After the device has passed its virtual tests, it is built with a 3-D laser printer that deposits polycaprolactone in thin layers until an exact replica of the virtual model is complete.

The process is both efficient and cost effective, the research team said. Each device can be printed in just a few hours and costs about $10 to produce.

The medical team can also use 3-D printing to produce a physical model of the patient’s trachea and bronchi. That way, surgeons can practice the delicate insertion procedure before actually operating on a child.

As patients grow, the cartilage around their airways becomes stronger, which greatly reduces the risk of collapse. Children usually outgrow tracheobronchomalacia by the time they are 3 years old.

“If the children are doing well at age 3 then we would expect them to do well for the rest of their lives,” Green said. “The airway has enough structural integrity at that point.”

The key, however, is getting children with the most severe cases to live that long. Green said that a few of the kids who were considered for the pilot trial died before the necessary paperwork was completed.

Plans for a larger clinical trial involving 30 patients are in the works, the researchers said.

Dr. Adnan Majid, a surgeon at Beth Israel Deaconess Medical Center who was not involved in the research, said the results from the pilot trial were promising.

“We do surgeries every day that involve stents and trachea repairs, but every stent has problems,” he said. “When they don’t fit perfectly they can migrate or the patient’s body rejects them. What 3D printing brings to us is the ability to customize patient care and prevent these complications.”

In the future, the researchers said similarly flexible devices created with the help of a 3-D printer could be designed to treat pediatric gastrointestinal, orthopedic or cardiovascular conditions.

“With patient-specific computer design and modeling, you can create anything that you can imagine to eventually become a medical device,” said Dr. Robert Morrison, a head and neck surgery resident at the University of Michigan who worked on the trial.

------------

FOR THE RECORD

A previous version of this post did not include the full name and description of Dr. Robert Morrison.

------------