Made in U.S.A. label advantages wear thin

Patriotism isn’t easy. Just ask L.A.’s garment makers.

Three years after combining their names to create Venley, a company that produces T-shirts and other basics in a downtown Los Angeles factory, onetime fraternity brothers Nick Ventura and Kevin Gressley find manufacturing clothes in the U.S. to be an expensive and frustrating undertaking.

Like many other apparel executives in the U.S., the pair pay more than the minimum wage, Ventura said. Sometimes, the same amount of money Venley shells out for locally made fabric gets Wal-Mart Stores Inc. an entire outfit sewed abroad.

But in light of the substandard conditions at a Bangladesh garment factory that collapsed in April, killing more than 1,000 workers, the idea of using overseas labor makes Ventura’s “blood boil.”

“The social benefits of staying local have come to the forefront for us,” the 26-year-old entrepreneur said.

Venley is part of a small Southland contingent of clothing companies, including American Apparel Inc. and 7 For All Mankind, that follow a hyper-local manufacturing policy.

They do it to support a nationalistic ideal or to keep a closer eye on production. Many feel a renewed sense of purpose after the Bangladesh tragedy. But the feeling is tempered by skepticism that their ranks will grow any time soon.

Many customers are still enamored with so-called fast fashion, preferring inexpensive foreign-made shirts to domestic options priced at a premium. Less than 5% of apparel sold in the U.S. is made here, compared with 95% in 1960, according to advocacy group Save the Garment Center.

“Companies are driven by what consumers buy, and nobody’s buying U.S.A. even though consumers preach about it all day,” Ventura said.

It’s a far cry from the post-World War II era, when the Southern California garment industry emerged. With immigrant seamstresses from Mexico, Europe and Asia offering a steady source of labor and hippie culture and grunge wear driving the popularity of California casual, the West Coast fashion empire steadily expanded.

Then the North American Free Trade Agreement blasted open trade barriers in the 1990s. Cheaper clothing imports flooded across borders, conditioning companies to search for even more affordable manufacturing in Asia once China emerged on the world stage.

Garment workers in the U.S. can command as much as $14 an hour, according to the Institute for Global Labour and Human Rights. Even after recent minimum wage increases overseas, their counterparts earn the equivalent of only 21 cents an hour in Bangladesh and $2.45 in Guangzhou, a hub of apparel manufacturing in southern China, government figures show.

The number of workers making apparel in Los Angeles County slumped to 45,500 last year, down 40% from a decade earlier, according to the California Employment Development Department. Nationally, more than 600 textile mills have closed since 1997.

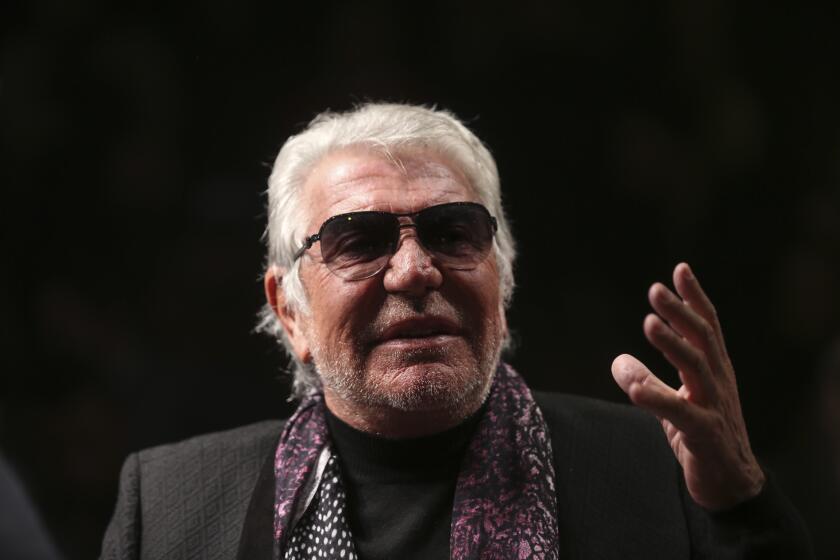

American Apparel Chief Executive Dov Charney, an outspoken advocate for the Made in the U.S.A. movement, lambasted companies that advertise very inexpensive clothing as selling “virtually stolen goods” made by underpaid workers abroad. American Apparel’s items are significantly pricier -- tennis skirts for $54, short-sleeved crew neck shirts for $20.

“It could be that over time, things will be made in a better fashion throughout the industry,” Charney said. “But there will be a big cost increase.”

The Los Angeles apparel market these days is built on smaller, entrepreneurial companies, said Ilse Metchek, president of the California Fashion Assn.

The local garment scene hasn’t died, “it’s just different,” she said. “We’re the little guy in the corner.”

Fashion labels Splendid and Ella Moss, for instance, relocated their headquarters in early June to a stylish 82,000-square-foot space in downtown’s Alameda Square. The two do 90% of their production in L.A.

In some industries, more American companies are considering a return to U.S. production, partly as a reaction to rising wages abroad as well as swelling costs to ship goods. On the home front, technological advances, especially in the auto and machinery sectors, have helped offset the high cost of U.S. labor.

But in the fashion world, tight margins and the need for human hands to drape and sew continue to make foreign factories appealing.

And working with a local contractor doesn’t guarantee humane employment practices. In December, federal regulators said they uncovered endemic “sweatshop-like” conditions in the downtown Los Angeles fashion district, including underpaid wages and lax or fake record-keeping.

When deciding where to manufacture, costs aren’t the only consideration.

Some companies can’t find enough trained workers in the U.S.

Thousands of Southland garment workers have been fired because they lack proper citizenship papers, Metchek said. Many of the young people who would take their place don’t have access to industrial training opportunities.

Loans for expensive manufacturing equipment are hard to get, she said. Tax credits are difficult to understand and qualify for.

It’s now common for classic U.S. brands such as California-cool label Stussy, workwear maker Carhartt and outdoor name Woolrich to manufacture large chunks of their products abroad.

“Woolrich strives to keep as much manufacturing here as possible, but companies today have little choice but to compete in a global economy,” the company says on its website.

Some efforts are being made to turn the tide. Wal-Mart pledged to buy $50 billion in U.S.-made products over the next decade. A few companies have launched special “Made in U.S.A.” collections in an attempt to reclaim their roots.

“Retailers prefer to stay here, as long as they can get a product at the right price,” said Bill Dombrowski, chief executive of the California Retailers Assn.

An added bonus, according to designer Deborah Viereck: Companies born and bred in the U.S. can carry a special cachet.

Viereck’s eponymous apparel collection is created almost entirely in and around a single 12-story building in the Los Angeles fashion district. Ten employees work in her 3,000-square-foot space on the top floor. Care labels come from the 7th. Trimming, pressing and finishing happens on the 10th. Local printers produce the summery ikat fabrics.

Her dresses aren’t cheap, retailing at $115 to $200 apiece. But they’re still snatched up by actress Angelina Jolie and other fashionistas -- many of them devotees of similar movements favoring artisan craftsmanship and fair trade goods.

Viereck, a native Angeleno who has designed for pop star Gwen Stefani, has seen her output to boutiques double each of the last five years. Nordstrom.com has come knocking.

“It would be cheaper to manufacture abroad, but it would definitely not be easier,” Viereck said. “Even here, with so much control, if a tiny thing goes wrong, everything goes wrong.”

Venley learned that lesson the hard way.

Early on, Venley produced tops out of a factory in Mexico, where minimum orders often require 3,000 pieces per style. Committing to the big order proved to be an overestimation of demand, and Venley landed on a pile of inventory that took twice the customary two to three months to sell.

“Going abroad has this allure of saving so much money and being superior,” Ventura said, “but we found it’s exactly the opposite.”

--