These solar workers will lose their jobs if Trump doesn’t get a China deal

President Trump’s trade war with China could cost American families an extra several hundred dollars a year for everyday items such as suitcases, furniture and shampoo.

But 150 workers at a central Washington solar factory face far greater consequences. If Trump doesn’t seal a trade deal by the end of June, they’ll lose prime jobs not easily replaced in farm country about 150 miles east of Seattle.

The trade drama playing out at REC Silicon — which makes polysilicon, the raw material for solar cells — illustrates the perils of levying tariffs, which can escalate and backfire. In this case, China appears to have outplayed the United States, using tariffs, subsidies and cheap financing to take over each step of the global solar manufacturing industry.

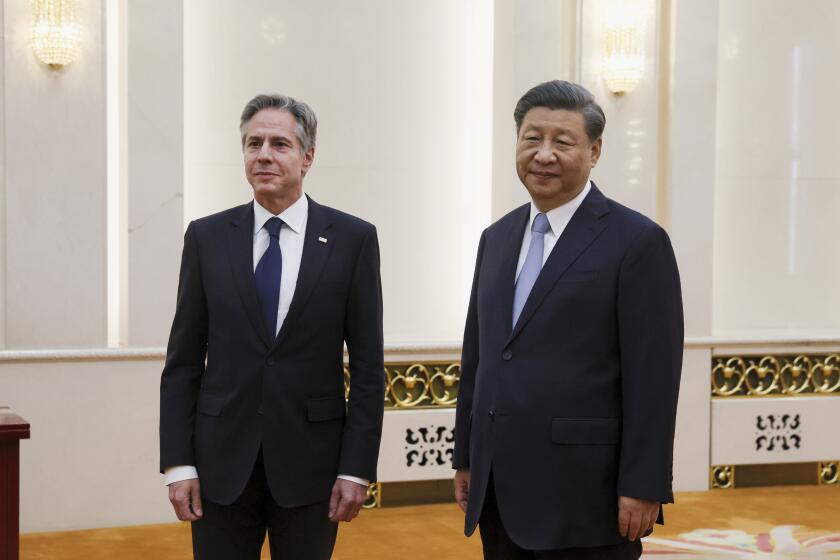

Even if Trump and Chinese President Xi Jinping meet and produce a breakthrough during the Group of 20 summit in Japan in late June, there’s no guarantee that the deal would remove the 57% Chinese tariff now crushing REC Silicon. And if it did, the company would still face challenges exporting to China, once its biggest customer, where rapidly expanding polysilicon producers have brought down prices and secured domestic sales contracts.

REC Silicon’s plant has reached the end of its endurance after multiple rounds of layoffs since its peak of 550 employees in 2013. The company, based in Norway, has invested $2 billion in the Moses Lake factory, which ended production May 15.

“We’re being strangled by China,” said Francine Sullivan, REC Silicon vice president of business development, who has become embittered by Chinese tactics. “Their business model is to take from everybody else, bring it to China and make it worse.”

Sullivan said that in contrast to REC Silicon, which found ways to cut intensive energy use and carbon emissions in purifying polysilicon, some Chinese manufacturers burn especially dirty coal to make the crystalline substance. She said that China’s concerted campaign to monopolize solar manufacturing has left the United States and other countries vulnerable to price hikes.

Although Trump has become known for aggressively taking on China, the U.S. solar industry’s trade war with the manufacturing giant actually began under President Obama. U.S. panel makers led by SolarWorld, a German company with an Oregon plant, lobbied the Obama administration to impose duties on the grounds that China was stealing market share by dumping below-cost modules in the United States.

In 2012, the U.S. Commerce Department under Obama slapped tariffs of more than 31% on Chinese panels. The move split the U.S. industry, with panel installers opposing tariffs, arguing that inexpensive imports encouraged homeowners to buy solar systems.

China retaliated the next year, imposing the 57% tariff that shut REC Silicon and other U.S. manufacturers out of the world’s biggest polysilicon market. Michigan-based Hemlock Semiconductor Group, which had just built a polysilicon factory in Tennessee, abandoned the project because of the Chinese duty.

“We literally tore out a $2-billion plant,” said Philip Dembowski, Hemlock’s chief commercial officer. In China, he said, “the duty renders us uncompetitive.”

Chinese companies moved some solar panel manufacturing to other Asian countries, ducking the U.S. tariff by exporting from abroad. Dembowski and Sullivan said that when offshore plants are taken into account, it’s evident that China has gone on to dominate world polysilicon production, expanding manufacturing while sheltered by the tariff.

China used state incentives, subsidies and tariffs to take over much of the rest of the global solar supply chain, according U.S. trade officials. China’s share of world solar cell production shot to 61% in 2012 from 7% in 2005, the Office of the U.S. Trade Representative said.

During the same period, low-priced panels from China helped triple the amount of solar generating capacity installed annually in the United States. But as Chinese companies grew to manufacture 71% of the world’s panels, the U.S. industry “almost disappeared,” with 25 manufacturers closing since 2012, the U.S. trade office said.

Now about 90% of panels in the United States are imported, according to the nonprofit Solar Foundation.

“People see the same thing happening potentially with other key industries like semiconductors or autonomous vehicles or artificial intelligence,” Dembowski said. “These are areas where China has significant amounts of investments going on.”

SolarWorld, which led the charge for U.S. tariffs on panels, went bust in 2017, blaming Chinese competitors for unfairly undercutting its prices. Now, SunPower Corp. is reviving the former SolarWorld Oregon plant, which the San Jose-based company bought for a fraction of the original investment.

U.S. solar manufacturing employment dropped 9% to 33,700 in 2018, a year when overall U.S. manufacturing jobs increased slightly. But U.S. solar installations have soared to 2 million, a number expected to double by 2023.

In January last year, the Trump administration slapped a 30% tariff on imported solar cells and panels. Once again, U.S. installers opposed the move, but REC Silicon and Hemlock executives felt that pressuring China with the tariff might pay off in trade talks.

As the conflict escalated with duties on an array of products, REC Silicon cut Moses Lake production to a quarter of the plant’s capacity. The company, which also operates a Montana factory supplying the semiconductor industry, lost $4.7 million on revenue of $45 million during this year’s first quarter.

China’s ability to turn the solar trade conflict to its advantage over the United States highlights contrasting approaches, said Xiaojing Sun, a senior research analyst at Wood Mackenzie Power & Renewables. While Americans eschew trade policy in favor of free-market innovation, Sun said, China enables its companies to cut production costs and swiftly expand, opening markets later.

In the United States, Sun said, “it’s hard to name a winner in this tariff war of the past six or seven years,” as polysilicon and panel makers struggle, and as consumers bear added costs from duties. “I’m pretty sure the U.S. polysilicon makers are never going to be able to rebound to where they were in 2012 before the U.S. tariff was imposed,” said Sun, a native of Tianjin, China, who is based in San Francisco.

U.S. solar players may be split concerning trade strategy, but people across the industry are tired of uncertainty over tariffs, said Andrea Luecke, president and executive director of the Solar Foundation. “It’s never positive for companies trying to close deals when the economics and financial returns could be dramatically, negatively altered by one swoop of the pen,” Luecke said.

Solar power generation continues expanding in both countries, accounting for 2.4% of electricity generation in the United States. The U.S. solar industry employs 242,000, a number that has slipped over the last two years as tariff worries slow installations.

California, with about 40% of U.S. generating capacity, still has the most solar jobs of any state, at 76,838. Starting next year, it will become the first state to require newly built homes to be solar-powered.

In Washington state, word that remaining REC Silicon employees will be laid off next month if China’s tariff persists disturbs workers like John Fisher, a product manager.

Fisher, 33, earned minimum wage as a Radio Shack store manager before joining the company in 2007. He got a substantial pay increase when starting at the plant, where the average salary including benefits is $100,000. He has advanced through a series of technical jobs.

“It’s very frustrating that it’s come to this,” Fisher said. “We have a unique, efficient process that’s the best in the world.”

More to Read

Start your day right

Sign up for Essential California for news, features and recommendations from the L.A. Times and beyond in your inbox six days a week.

You may occasionally receive promotional content from the Los Angeles Times.