CEO Seeing Green With Rented Carpet

The first industrial revolution began with a spinning machine. The second, Ray Anderson hopes, will begin with rented carpet.

Anderson is founder and chairman of Interface Inc., which makes carpet and carpet tiles for offices, stores and airplanes. He is a pioneer in carpet leasing--installing and maintaining carpet for a yearly fee rather than selling it to the customer.

Rental carpet is good for the environment because it allows the manufacturer to make sure worn-out carpet is recycled rather than dumped in a landfill, said Anderson, whose company is the world’s No. 4 carpet maker.

His “Evergreen Lease” is part of a long-range plan to operate Interface without using non-replaceable resources and without producing harmful byproducts. He’s trying to prove that it’s possible to accomplish what environmental author Paul Hawken calls the second industrial revolution--when industry becomes the world’s leading environmentalist.

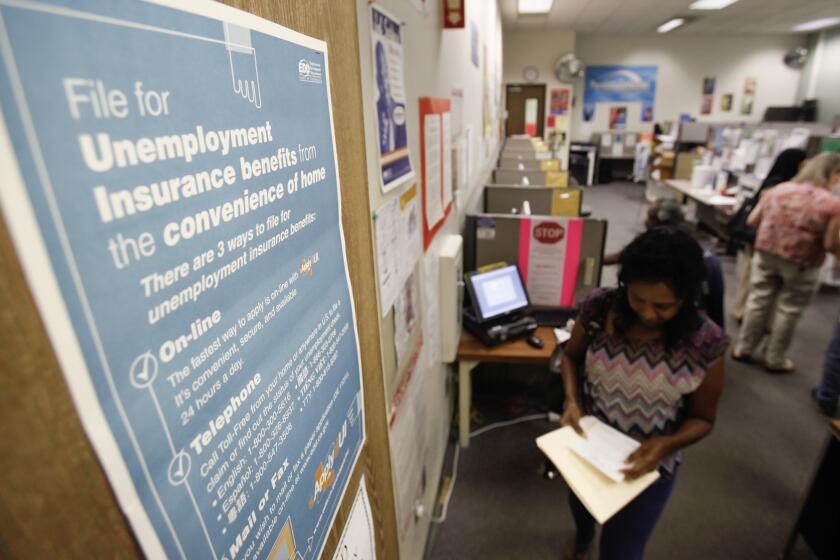

Only two customers, the Southern California Gas Co. Energy Resource Center and the city of San Diego, have signed up to lease carpet from Interface in the three years that it’s been available. Others have been reluctant, either because they don’t want to commit to the minimum 21-year lease or because banks have been skeptical about financing.

But Anderson said the long-term cost of leasing is less than buying because the carpet--which is replaced tile-by-tile as high-traffic areas get worn--lasts longer and customers don’t have to worry about disposal. Many landfills refuse to take old carpet because it won’t decompose.

“What Ray is doing is truly pioneering,” said Alex Wilson, an environmental biologist and editor of Environmental Building News, a newsletter for architects, builders and developers. “He’s being scoffed at by some in the mainstream of American industry, but in the long term he’s going to go down as a real leader in the transition.”

In his quiet, expansive office in northwest Atlanta, the soft-spoken, 63-year-old Anderson doesn’t look like a revolutionary.

He grew up in the mill town of West Point, Ga., learned in college how to make mills run, worked his way up in the industry and built his own company.

There seemed to be no more mountains to climb. But in 1994, Anderson was asked to talk to Interface managers about his environmental vision. He had nothing to say.

“I was rather desperate to find a vision I didn’t have for a speech I didn’t want to make,” he said.

Someone gave him Hawken’s book, “The Ecology of Commerce,” which he says shook him profoundly. “It was well orchestrated by some higher power,” he said.

He read more. He talked with authors and scientists. He decided it was time for industries to learn to operate without harming the Earth. Finally, he decided to make his industry one of the first.

The textile industry is energy-intensive: Oil is mixed into the recipe for nylon carpet fibers; coal powers the huge looms; gasoline runs the trucks and planes that deliver raw materials to the mills and finished products to customers. Plant emissions contribute to global warming.

If Interface could do it, Anderson thought, anyone could.

He hired three scientists to work full-time on environmental research, including figuring out how to power mills with sunlight. He assembled an “Eco Dream Team” of six paid advisors to come up with new ideas.

His 6,000 employees have contributed thousands of small ideas to cut waste, adding up to a two-year savings of $25 million.

Company scientists have found ways to grind old carpet into a powder that’s used in the base for new. They’ve learned to make carpet with less yarn but more durability.

Anderson also is working on a “closed-loop” manufacturing process, one that doesn’t use fossil fuels or any other non-replaceable resource.

Interface is alone among the large textile companies in this effort, although one smaller textile maker, New York-based DesignTex, is making inroads into closed-loop manufacturing, said Wilson, adding it will be a daunting task.

Tony Occhionero, who designed and built the Southern California Gas center in Downey, said he was attracted to Interface carpet because it included recycled materials and would not end up in a landfill.

“We were looking for the first recycled commercial-grade carpet, and we got more,” he said.

Although customers are still few, Lorraine Miller, an industry analyst with Robinson-Humphrey, said Anderson’s carpet lease plan should prove popular in the long run.

“It’s a new, revolutionary plan, and every change in this industry takes a while to take hold.”