Goldsign’s Adriano Goldschmied shows how premium denim is made

Looking at a pair of premium denim jeans (you know, the kind that cost upward of $120 and are generally found in department stores and specialty boutiques), it can be easy to miss some of the tiny details, deliberate nicks and distressing that go into the design.

The process of transforming a garment with origins in sturdy, utilitarian work wear into something pricey, fashion-forward and sometimes sexy requires lengthy design sessions, an intricate fit process and hours at a wash house where denim is treated like a science experiment-meets-an-artisan-workshop rather than a mass-produced basic churned out by the thousands in a factory.

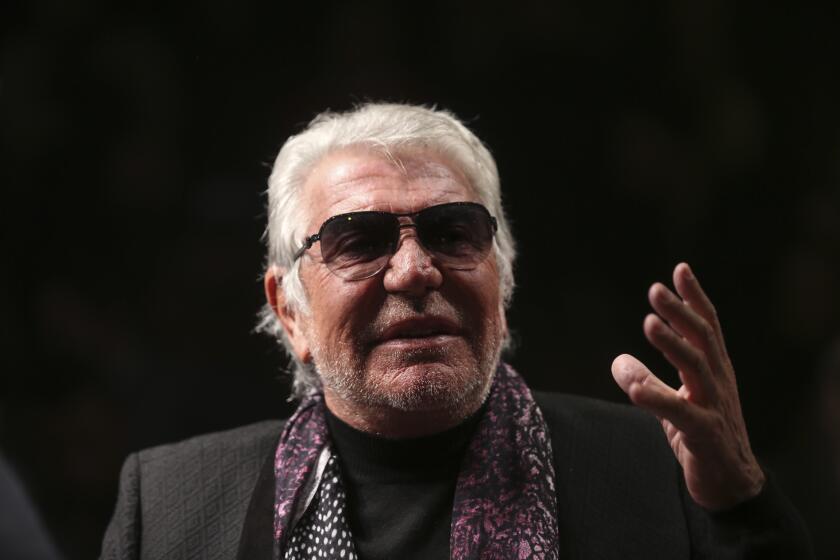

“Basically everything is done by hand,” Adriano Goldschmied says, referring to the washing and fabric treating process. The founder and creative director of Goldsign Jeans and creative director for Citizens of Humanity men’s line spends much of his time in his denim laundry facility in Gardena experimenting with new washes for his lines. He’s referred to by many in the fashion industry as the “godfather of denim,” having started and developed a number of denim companies, including Diesel, Replay, AG Adriano Goldschmied and his current obsession, Goldsign.

Goldschmied walked us through the steps he uses to get a pair of raw boot-cut jeans to look perfectly worn in, distressed and creased in all the right places.

The jeans are thrown into a washing machine with a soap that helps to break down the fabric and contrasts the blue and white yarns.

The jeans are then put into an industrial-size washing machine filled about halfway with Turkish pumice stones, which create small abrasions on the edges of pockets and along the hem of the pants.

Then the jeans are rinsed in cold water to eliminate the soap as well as any powder or residue formed during the stone-washing process. They are placed in an extractor to remove excess water until they are just slightly damp.

Next? Forty minutes in a 140-degree dryer.

Once dry, the jeans are dipped in a vat of resin to stiffen them and prepare them for the sanding and abrasion process.

Another trip to the extractor eliminates excess resin.

By this point, the jeans begin to exhibit a slightly stiff yet moldable texture ideal for deliberate creases. The pants are pulled onto a machine that is essentially the bottom half of a mannequin to create pleats around the upper thigh area and hip area — all done by hand, so no two pairs are exactly the same.

After the desired creases and pleats are made, a large black bag is zipped around the jeans and filled with air heated to 170 degrees. The heat “cures” the resin enough so that the jeans can be removed from the mannequin, hung on a rack and fed into a large 330-degree oven for 15 minutes to cure further.

Emerging from the oven, the jeans are dry and ready for sanding. They’re placed on another mannequin for what Goldschmied calls “local abrasion,” a process designed to enhance the texture and increase the color contrast in the fabric. Using a square of sandpaper made especially for working with denim, an employee sands specific areas on the pants. “The sanding breaks up the indigo, so the white color of the thread inside comes through,” Goldschmied says.

He then dips a cloth in chlorine and goes back over the area he has just sanded to make the white areas even more white.

The jeans are washed yet again to neutralize chemicals used in processing and remove any residue created in the sanding process. (Some styles are treated with a tool that resembles a drill head with coarse sandpaper attached to it, resulting in an “aged” finish.)

Finally, the jeans are placed back on the mannequin for some browning and aging detail, which is accomplished with a torch. A finisher runs the flame lightly over some of the whiter areas to lessen the contrast.

The entire process — washing, stoning, curing and creasing — takes about six hours.