Chairs Sit Well With Laborers

For nearly a decade, Kwei Fong Lin tolerated numbness in her forearms. Like a great many Chinese immigrants who work in this city’s cramped and poorly equipped garment factories, her neck and back ached from long days spent hunched over a sewing machine while perched on rickety folding chairs, stools or even crates.

“We just took the pain as it came,” the 52-year-old Hong Kong native said in Cantonese.

But an unlikely revolution has taken root here. Today, dozens of women work in relative comfort while seated on customized ergonomic chairs. Simple table extensions relieve their tired shoulders. Wooden footrests keep their legs from dangling. Padded sleeves cushion the metal rods they must press hundreds of times a day with their knees to clamp and release fabric.

A city grant will soon bring the ergonomic equipment to other garment shops that dot Oakland’s Chinatown and other commercial strips. And the project has spawned a much larger study now underway in Los Angeles County -- the heart of California’s rag trade.

Most surprising in an industry synonymous with powerless and mistreated workers: The women made it happen. They did it with the help of a group of teenage girls tired of seeing their seamstress mothers suffer, and a team of medical professionals, ergonomics experts, state health officials and product designers.

Low-wage immigrant workers -- most with no health insurance -- are not likely to file workers’ compensation claims, said Jackie Chan, an industrial hygienist with the state Department of Health Services involved in both the Oakland and Los Angeles programs. Because state inspections are triggered only if two workers doing the same task are injured in a 12-month period -- and report it -- ergonomic concerns in the garment industry have largely fallen below regulators’ radar, she said.

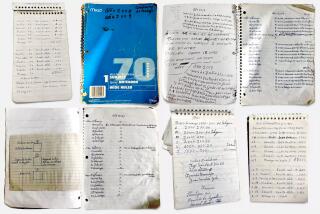

But the Oakland women overcame fear and language barriers to make a change. First, they had to face their pain and seek treatment. Then, over countless boxes of Chinese take-out, they were measured, studied and surveyed in a makeshift sewing laboratory until the best -- and most cost-effective -- designs were complete.

“We’ve done something we never thought we could do,” said Lin. “The workers in Oakland now know there’s an ergonomic chair that’s good for their health. Everybody’s talking about the chair.”

Much of the clothing once manufactured in the U.S. is now mass-produced overseas. But complex garments and high-end women’s fashion, which demand quick turnaround and constant changes, are still made in small contracting shops in this country.

Oakland’s sewing machine operators are almost all from Hong Kong and the Chinese province of Kwang Tung. The nonprofit Asian Immigrant Women Advocates was founded two decades ago to help them improve their lives, but ergonomics was never on the agenda -- until the workers and their daughters put it there.

By the late 1990s, the teens were walking picket lines on behalf of their mothers to compel large manufacturers to take responsibility for the conditions in small contracting shops. Their mothers came home exhausted, complaining of headaches, backaches, and pain in their arms and hands.

Meanwhile, the organization was training seamstresses who gathered for evening English classes to teach their colleagues about health and safety issues. They surveyed their colleagues on the job and drafted a list of key concerns.

“They hurt all the time,” said Nan Lashuay, an assistant professor at the UC San Francisco School of Nursing, who helped train the women.

Just how prevalent the injuries were, no one knew. So, with the help of Robert Harrison, a leading UCSF occupational and environmental medicine specialist who also heads the Department of Health Services’ occupational health section, a clinic opened four years ago in a borrowed room downstairs from the Oakland nonprofit.

With a small grant, and translation help from the teens, the collaborative effort to document -- and treat -- the women’s aches got underway.

The job of spreading the word fell to the daughters, who prowled Oakland’s garment factories with fliers encouraging the women to seek treatment for pain. “At first we were so scared,” said Winter Xie, now 19. “The people just shut the door right in our face, or they’d yell at us. Or the workers wouldn’t accept the fliers. They were scared of their bosses.”

Still, the women streamed into the evening clinic. Beate Ritz, a UCLA epidemiologist who is heading the Los Angeles study, said women in pain were more likely to come, skewing the results. But the findings nevertheless hinted at crisis.

Of the first 100 patients to visit the clinic, a report released in 2002 revealed, 99 had one or more work-related conditions. Nearly half were diagnosed with back strain or pain, one-third with neck strains, one-fourth with shoulder strain or pain, and 9% with wrist and knee pain. More than half said pain kept them awake at night and impeded their housework. Nearly one-third had trouble dressing or bathing.

Just seven had filed workers’ compensation claims, and four of them said they were fired or forced out of their jobs as a result. “It was a learning process for the garment workers to identify that pain wasn’t normal,” said Lashuay, who served as clinic director. “ ‘You work, you use up your body.’ I heard that statement so many times.”

Under the guidance of Chan, of the Department of Health Services, the women learned to relieve their symptoms by stretching, applying ice and taking ibuprofen. But when they were encouraged to confront their bosses about poor working conditions, most balked. Many were even reluctant to accept pieces of sturdy foam to use as lumbar support cushions or pad their hard-edged sewing tables, fearing that even slight changes to work equipment might rile their employers.

But slowly, the women began to speak up. One was teaching her colleagues stretching exercises at their sewing shop when her boss appeared. She feared she would be fired, but her supervisor was encouraging. The woman recounted her experience in a video testimonial, distributed to other workers. Maybe, they realized, they could change their workplace.

“Seeing doctors is not a long-term solution,” said May Yeung, 50, a shy Hong Kong immigrant. “Prevention is better.”

With the women’s urging, the nonprofit organizers and clinic health practitioners decided to take the project one step further. Because there was no ergonomic equipment available for the garment industry, they would have to create some.

The final phase of the project convened in a makeshift lab in the nonprofit’s offices. Chan and Lashuay recruited Ira Janowitz, a senior University of California ergonomics consultant.

Ergonomics improvement programs are generally initiated by management and conducted at the workplace, said Janowitz. Low-wage workers forming their own ergonomics committee was highly unusual, he said.

Industry conditions also startled him. Workers often sat on crates or stools to sew, factory visits and photos revealed. Those who had chairs adjusted them by jamming spent plastic thread spools under the rear legs.

The new equipment had to fit the factories’ cramped conditions. And it had to be inexpensive if the group had any hope of promoting it to Oakland’s immigrant-owned contracting shops.

Janowitz called on Carl Zdenek, a former architect and founder of Bay Area-based Soma Ergonomics. Much like musicians, sewing machine operators engage in what ergonomists call “forward sitting.” Zdenek had already helped design a two-part chair that tilts forward to accommodate that posture in cellists. The garment workers’ ideal chair, he decided, would look similar. An Oakland cabinetmaker and a sewing machine mechanic from San Francisco rounded out the team. Together, they devised a footrest that factory owners can make themselves for as little as $5, and a sewing table extension -- which sells for $40 -- that raises and lowers to accommodate heavy fabrics that tire the women’s shoulders.

Finding factories to take the test designs -- even for free -- was not easy. “Nothing is free in the Chinese culture,” said Ken Fong, a longtime AIWA organizer who with Chan visited the same factories repeatedly to persuade them to take the chairs. “They thought there must be some conditions we were hiding.”

At last, three signed on. On regular visits to the factories, Chan brought dim sum, needles to replace ones that broke, and other offerings to signal goodwill. Then, two years ago, the first chairs arrived.

Although the Oakland group is too small to be scientifically significant, Chan said, the majority of women in follow-up surveys have reported a reduction in pain. The preliminary findings led to the study now underway with 300 workers in Los Angeles County.

At W&S;, a small factory in an unmarked Oakland building, the industry’s harsh realities and the ergonomics project’s tentative hope are both in evidence. On a recent day, about two dozen women hunched over machines -- many sewing satin pink and black Jessica McClintock evening gowns.

One woman who identified herself only as Lisa said she had grown accustomed to constant lower back and leg pain. Because she has no medical insurance, she has never gone to a doctor.

Now, her left foot rests on a wooden platform as her right works the sewing pedal. A simple cardboard toolbox keeps her from twisting and reaching for what were once the scattered implements of her trade. A cushioned sleeve protects her right knee. And a table extension means her left shoulder need not bear the full weight of the gowns. But the greatest relief, she said, has come from the chair.

“It’s more comfortable,” Lisa, 50, said through an interpreter. “It can raise up and down.... Now I’m happy.”

W&S; owners Sing and Wing Ma bluntly tell Fong they want more free chairs. They love them, they say, but they cannot afford to buy them. Some months, Wing Ma said, he bleeds as much as $10,000. “I can’t put in money if I am losing money,” he said.

Last fall, county funding allowed the ergonomics project to expand beyond the model factories. But contractors were still reluctant to purchase the chairs -- which sell for about $160 -- so AIWA created a chair “library,” lending the equipment to participating factories for about one-tenth of their retail value.

Among the recipients is Mimi Chung. Chung curls her frame over a sewing machine next to her employees at the family-run Hong Hing Sewing in Oakland’s Chinatown. She knows all too well how the body can ache.

“With the chair now, the sitting posture holds my back,” she said. “I feel more comfortable and don’t so easily get tired.”

Chung rented 10 chairs through the library. Her husband built footrests based on the suggested AIWA design, and the couple rigged a version of the table extension from hard-surfaced boxes. Earlier this year, Chung and dozens of garment workers and youths successfully pleaded with the Oakland City Council for a $25,000 economic development grant that would bring 135 additional chairs to up to 15 more factories through the chair library.

When the council awarded the money, garment worker May Yeung wept.

“These 135 chairs are not the end of it,” said Yeung. “This project should be known nationwide and throughout the world -- for making working conditions safer.”

More to Read

Start your day right

Sign up for Essential California for news, features and recommendations from the L.A. Times and beyond in your inbox six days a week.

You may occasionally receive promotional content from the Los Angeles Times.