FAA Investigating Safety of Questionable Boeing Parts

- Share via

The Federal Aviation Administration is investigating whether more than 2,000 allegedly counterfeit ball bearings placed in Boeing-made 737, 747 and 757 jetliners manufactured after July 1, 1986, pose a safety threat to passengers.

“The FAA has a team of investigators over at Boeing,” said David Duff, an FAA spokesman in Seattle, where Boeing is based. “Is there a safety problem? That is our main concern. If we identify anything in that area, we will take care of it immediately.”

Boeing has declined to say how many jets contain the allegedly bogus bearings or to which airlines the planes were sold.

Discussed Investigation

Since July 1, 1986, Boeing has manufactured a total of 490 Boeing 737, 747 and 757 aircraft, the company said. That works out to about 20% of the 2,425 Boeing aircraft of those types in use worldwide. The Boeing jet that crashed Wednesday at Dallas-Ft. Worth International Airport was a 727.

Boeing spokesman William Clark said Thursday: “There were some representatives from the FAA here today and we discussed the status of our investigation with them. Beyond that, you’re going to need to go to them to find out their future plans.”

On Saturday, The Times reported the existence of the allegedly bogus ball bearings. The information was in a lawsuit filed in U.S. District Court in Los Angeles by an airplane parts manufacturing company.

Experts say the bearings, which are washer-shaped and about the diameter of a golf ball, typically are used in several flight control areas: the airplane’s gear box, the pilot control systems, which are used by the plane in changing altitude, and the plane’s trim tabs, which help keep the craft level in flight.

Have Caused Problems

Last week a Boeing spokesman said that “so far, none of the applications discovered have been flight-critical or safety related.”

But a check of FAA records in Oklahoma City showed that bearings with the same numbers as those allegedly counterfeited have caused problems. Legitimate bearings also carry those numbers.

On Jan. 21, a Boeing 737 operated by Southwest Airlines had to return to Houston’s William P. Hobby Airport immediately after takeoff because of “erratic movement of stabilizer trim wheel.”

The trim wheel helps keep a plane level during flight. The Southwest flight landed safely.

There have been similar incidents due to the failure of the same type of bearing.

In 1981, a Boeing 737 had to make an unscheduled landing because of a jammed stabilizer trim wheel. FAA records indicate no one was injured in the landing.

And in 1984, the pilot of a Boeing 727 reported another jammed stabilizer trim wheel. The FAA report said the bearing had disintegrated.

The allegedly counterfeit parts were first mentioned publicly in a July 28 lawsuit filed by Torrington Co., a Torrington, Conn.-based ball bearings manufacturer, against Alliance Bearing Industries of Van Nuys, a parts distributor.

Blame One Employee

Torrington Co., which is owned by Ingersoll-Rand, sued Alliance, charging it with trademark counterfeiting, trademark infringement, unfair competition and racketeering.

Alliance has denied the charges but admits that some of the more than 10,000 bearings it sold to Boeing were not the bearings that the labels said they were. Alliance says the alleged counterfeiting was the work of one employee.

A Torrington engineer, Alan Gabrielson, said in the lawsuit that the bearings could “pose serious hazards.”

Still unknown is how the bearings passed Boeing’s quality control system. “We’re going to find out how this happened,” said the FAA’s Duff, “and make sure it never happens again.”

The FAA refused to say whether it was considering grounding any of the Boeing planes.

More to Read

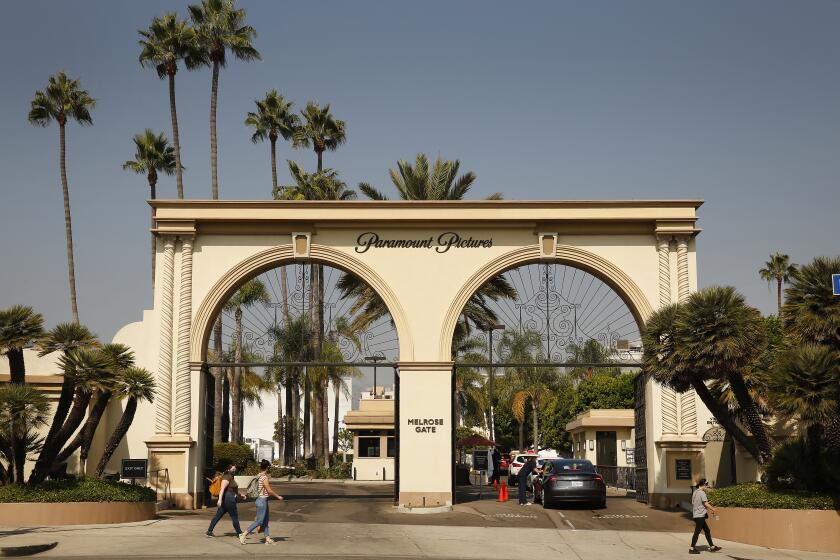

Inside the business of entertainment

The Wide Shot brings you news, analysis and insights on everything from streaming wars to production — and what it all means for the future.

You may occasionally receive promotional content from the Los Angeles Times.