Master Knife Maker Looks Forward to the Daily Grind

- Share via

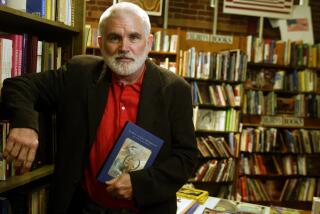

Charlie Davis examined the knife carefully, and a smile slowly formed behind his bushy beard. His eyes danced behind the round face, as if he had suddenly recognized an old friend.

“I remember this one ‘cause I only did a couple like this back in ’84. You got a real good one,” Davis said.

The subject of Davis’ pride and joy was a 6-inch blade, slightly curved, with a dark hardwood handle. The owner, equally proud of the knife, is a deer hunter and said he used the knife to butcher game animals.

“I’ve cut through pelvic bones with this thing,” the hunter said. “A lot of times, I’ve been around the campfire, taken my knife out, and everyone always wanted to know where I bought it. You don’t find knives like this in a sporting goods store. It’s one of a kind.”

Davis, 40, is a craftsman and artisan; a master knife builder whose unique products are coveted by knife lovers and collectors throughout the country. From his small Lakeside shop, Davis and his 17-year-old son, Chris, manufacture practical and showpiece knives for people who are willing to pay as little as $15 for carving knives or much as $600 for displays.

“Some of them may look fancy to you, but I call my knives ‘working knives,’ ” Davis said. “Of course, once my knives are taken out of Lakeside, their price usually goes up. I’ve sold knives for $15 that people turn around and sell for $40.”

Davis’ knives can be bought in exclusive cutlery shops at places like Horton Plaza and at the Acorn Shop in Gatlinburg, Tenn., internationally known as the world’s largest knife shop.

He has been making knives almost 21 years, and in 1980, after working at Buck Knives in El Cajon for 14 years, Davis founded Anza knives. The name picked by Davis for his company reflected some of the marketing lessons that he had learned at Buck, where he had risen through the ranks to become production superintendent before he left the company.

“I wanted a four-letter word. After all, it worked for the other guys. . . . When my knives get back East they ask, ‘Anza. What the

hell’s an Anza?’ Hell, you could use the same name on perfume and it’d sell.”

Unlike most knife makers who use tooled steel, Davis takes ordinary high-carbon steel mill files and horseshoe files and turns them into a variety of models with blades ranging from 3 inches to 14 inches long. He purchases the files from the manufacturer, but he is also known to frequent swap meets and garage sales to buy old files.

Davis’ shop is rather eclectic, and his knives share shelf space with baseball cards, used paperbacks, used boots, an assortment of curios, dishes, stuffed toys and other discarded items. A sign on the door says that he is willing to trade for used files.

“Knives and a thrift store, that’s my business. If I can’t sell you a knife, maybe you’d be interested in something else,” he said, laughing.

While Davis was talking, a city fellow walked in and was immediately attracted to a long row of used cowboy and working boots on a shelf. The man looked lovingly at a pair of silver eel-skin boots.

“Hey, they fit!” he said with surprise. He plunked down $16 for the boots and walked out wearing them.

The handles on Davis’ knives are almost as exclusive as the blades themselves. Typically, Davis uses a laminated hardwood for handles. But custom knives can also include handles carved and polished from deer, elk, moose, cow or buffalo bone.

One of his current showcase knives is a Bowie with a 9 3/4-inch blade, 1 3/4 inches wide. The knife has a polished and scrimshawed handle made from cow bone, with a picture of the Alamo carved on one side and a Longhorn on the other. This one-of-a-kind knife--made from a horseshoe file--sells for $450.