How I Made It: Designer jumped into the 3-D printing game at just the right time

- Share via

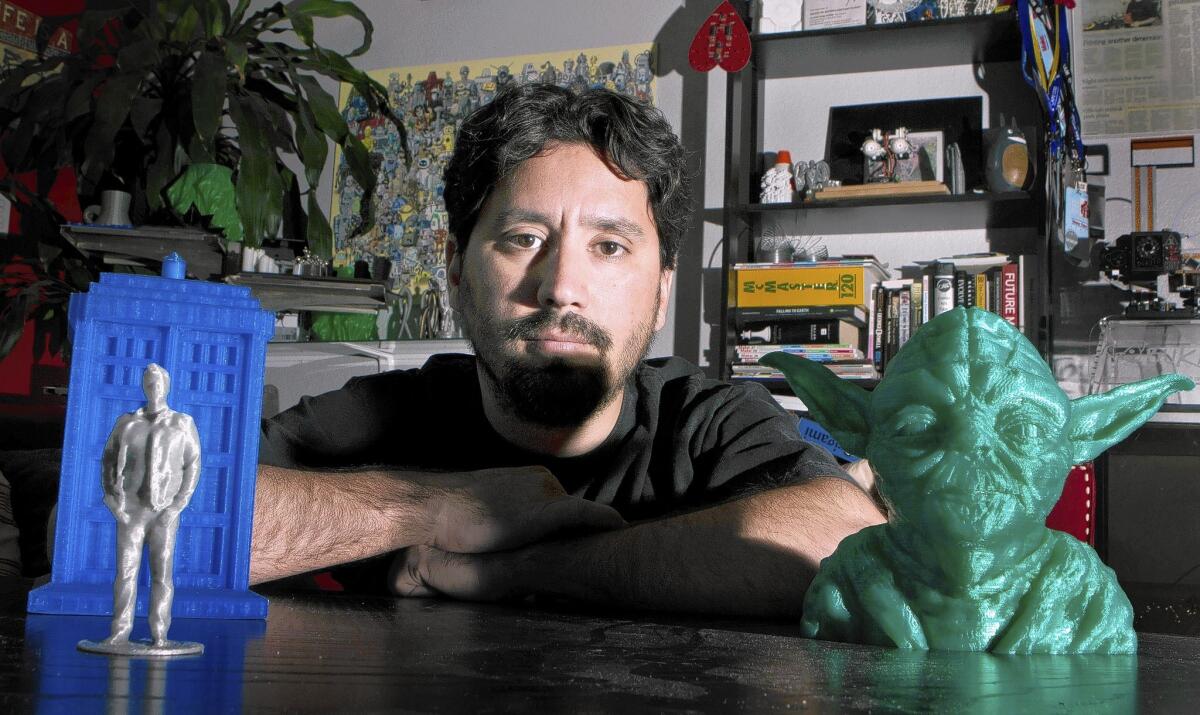

The gig: Diego Porqueras, 39, owns Deezmaker, one of the nation’s first commercial 3-D printing shops. After two successful Kickstarter campaigns funded production of his 3-D printer, Porqueras moved his business from his garage to a store in Pasadena. He employs a handful of designers and technicians who manufacture 3-D printers, help customers with projects and look for ways to add features and contribute to the growing 3-D printing community.

The template: Born in Argentina, Porqueras moved to Southern California when he was 3. While attending Corona’s Centennial High School, he took an interest in the school’s machine shop where he built, among other things, a working steam engine and sail-assisted remote control cars.

On-the-job training: Porqueras’ many interests took him into an odd collection of jobs, including night-shift technician at a Christian radio station, print shop graphic designer, Web designer, audio system installer, photographer and Hollywood camera technician. Those experiences came in handy when Porqueras was trying to get Deezmaker off the ground. “I was a one-man show in the beginning,” Porqueras said. “I designed my machines, figured out software for it, started doing 3-D design basically on my own. I’m into photography so I did my own photo shoots, I did my own videos.... I used everything basically in my skill set.”

The ABCs of 3-D: Porqueras first heard about 3-D printing during a short CNN report in the summer of 2011. He was intrigued and began researching the area. Although the technology has existed for decades, only recently have 3-D printers come down in price and size, becoming more suitable for consumers. Using a variety of materials, mainly plastic polymers, 3-D printer owners have been able to create items such as toys, sculpture and casts for broken bones.

Inventing his future: Porqueras became frustrated with the limitations of the technology. He decided to design his own machine, called Bukobot after his dog, a lab-mastiff mix named Buko. He put the project on Kickstarter, a crowd-funding website where visitors can pledge money in return for a reward or prize. Porqueras set a goal of $42,000 to get started and ended up with more than $167,000 in funding by March 2012. He quit his camera tech job to focus full time on 3-D printing.

Good timing: Because Deezmaker was the second 3-D printing shop to open in the U.S., Porqueras said the store has gotten more exposure and attention than if it had opened later. “If you’re too early, it takes a while to recover what you invest, and if you’re too late, you have too many competitors in the market,” he said. “So I think we landed in the right spot.”

Open sourcing: Porqueras said one of the main reasons for Deezmaker’s success is that he makes all of his code and technology available on the company’s website, which people can access to use for their own projects. Though sharing company secrets may not seem as if it makes much business sense, Porqueras said the idea of being open source is central to Deezmaker’s philosophy and helps spur innovation.

“We like to share things,” he said. “We know it’s a little risky in business to share too much information, but at the same time, it pushes us to challenge ourselves to innovate faster or better to be ahead.”

Business basics: Customers can place orders for 3-D printed objects or have items scanned that can then be printed at sizes ranging from 1 millimeter to 8 inches, square. Printers cost $899 to $1,499. Porqueras said the prices were set at a level to provide the best value for the consumer without sacrificing quality.

“We’re not looking for people who are trying to be cheap about everything, and we’re not looking for people who want a luxury engineering machine,” he said. “We’re trying to reach that Toyota/Honda-ish kind of level.”

On the move: “Right now, the 3-D printing game is moving pretty fast,” Porqueras said. “Every couple of weeks, someone comes out with something new, something cheaper, something faster.”

Several weeks ago, Deezmaker’s design team added stability features to the printer, meaning it could be flipped and jostled and still print normally — a feature that could prove useful in low-gravity situations.

Porqueras said he is dedicated to walking the fine line between innovating for Deezmaker’s benefit and expanding the 3-D printing industry. “We’re not trying to stomp on everybody. We’re kind of competitive in the community,” he said. “Instead of trying to shoot each other down, it’s the opposite: We’re trying to out-innovate everybody.”

Twitter: @RileySnyder

More to Read

Inside the business of entertainment

The Wide Shot brings you news, analysis and insights on everything from streaming wars to production — and what it all means for the future.

You may occasionally receive promotional content from the Los Angeles Times.