Packing T-shirts? There’s a Uniqlo robot for that

- Share via

There was only one job that robots could not do when Fast Retailing, the owner of Uniqlo, replaced 90% of its workers with robots at its flagship warehouse in Tokyo last year.

But now, with the help of a Japanese start-up called Mujin, the world’s third-largest retailer says it has cracked the final barrier to full automation, a priority for Uniqlo as Japan’s aging population creates labor shortages.

The two companies have invented a robot with two arms that can pick up soft T-shirts and place them neatly in boxes to be shipped to customers.

While it sounds easy, the ability to lift soft textiles has been a challenge for clumsy robotic arms. Add to this the need to sort through constantly changing seasonal clothes, in shades that are hard to distinguish and wrapped in various forms of packaging, and humans have always come out on top.

Even the most aggressive believers in automation, such as Amazon, still depend on human “pickers.”

“We’ve been putting off working with an apparel company because it’s so difficult,” said Issei Takino, co-founder and chief executive of Mujin. “But Fast Retailing’s strength is its ability to overhaul its entire supply chain to make it fit for automation. If we’re going to take on this challenge, we had to do it with Fast Retailing.”

Founded in 2011, Mujin develops robot motion and vision systems, such as 3-D cameras. After human operators set up a machine with Mujin controllers, it can see and move without having to be repeatedly programmed.

For Fast Retailing, which sells 1.3 billion items of clothing a year, the need for automation is urgent, given a shortage of workers and rising storage costs.

“It’s becoming extremely difficult to hire workers, and it’s a lot more than people think,” said Takuya Jimbo, a Fast Retailing executive in charge of changing the supply chain. “We have to be the front-runner and continue trial and error because only the companies that can update their business models can survive.”

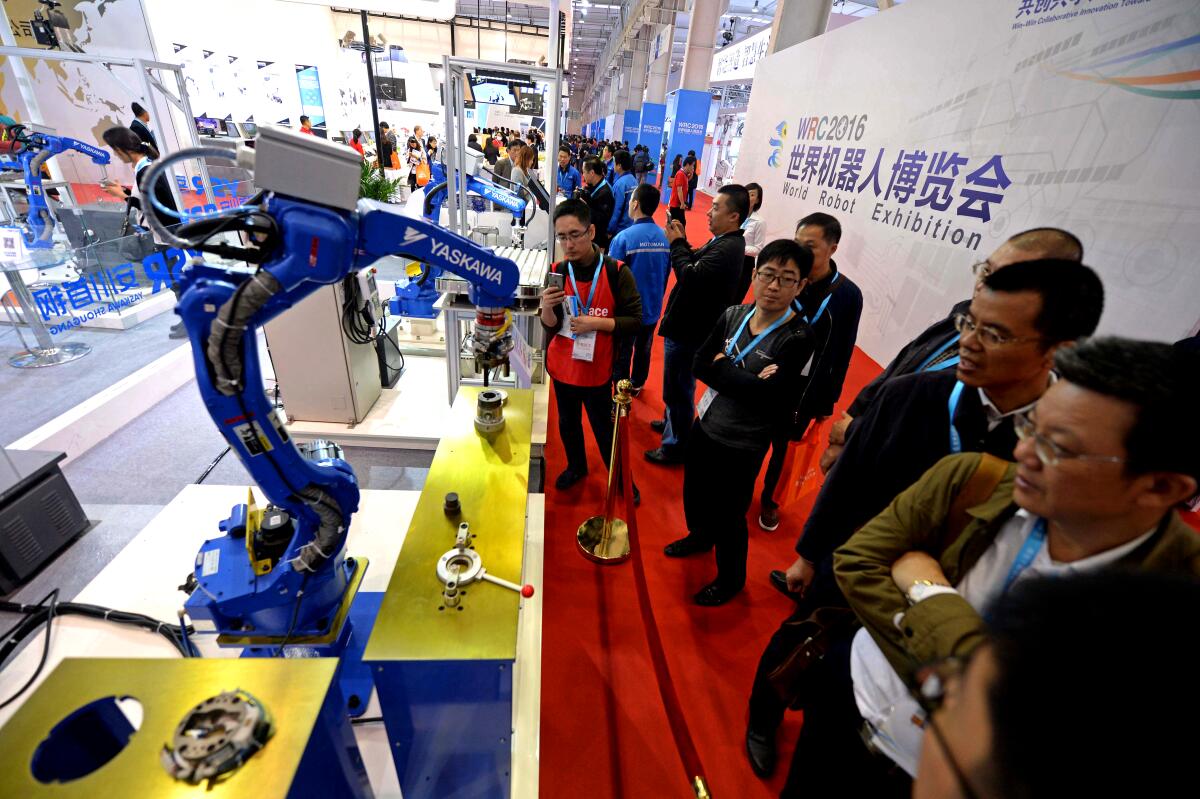

The jointly developed robot, which was made by Yaskawa Electric Corp., is already operating in Fast Retailing’s main warehouse in Tokyo, but Takino admitted that the robot was not able to handle all of the facility’s products, and that it needed further development.

For instance, the plastic packaging of the thermal underwear in Uniqlo’s Heattech line is relatively simple for the robots to pick up, but this could become more difficult as Fast Retailing aims to switch to more eco-friendly paper bags.

The robots are able to pick up belts, but they typically become unbundled as they are dropped into boxes. One solution would be for Fast Retailing to ensure that belts are sold in bundled forms.

© The Financial Times Ltd. 2019. All Rights Reserved. FT and Financial Times are trademarks of the Financial Times Ltd. Not to be redistributed, copied or modified in any way.

More to Read

Inside the business of entertainment

The Wide Shot brings you news, analysis and insights on everything from streaming wars to production — and what it all means for the future.

You may occasionally receive promotional content from the Los Angeles Times.