Sun Valley Manufacturer a ‘One-Stop Shop’ : Family Paper Business Contained Seed of a Bigger Package

- Share via

Marfred Industries had humble beginnings. Originally a retail paper business, the Sun Valley-based box manufacturing and distribution company was started in 1963 by Rubin Fenster in the back room of his Glendale grocery.

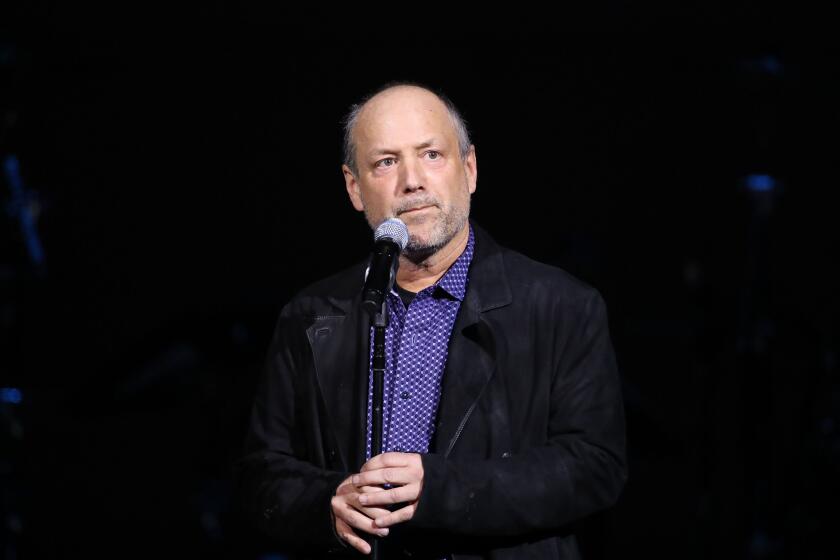

“Some people want to be doctors and others want to be lawyers,” said Marvin Fenster, Rubin’s son and Marfred’s president since 1968. “My dad always wanted to be in the paper business.”

It didn’t take much inspiration, however, to put Marfred on the path that turned it into what the company says is a $30-million-a-year business.

One Fateful Day

As Marvin Fenster, 45, a soft-spoken, baldish man who sports a thick gold bracelet tells it, he was visiting a supplier in his father’s station wagon one day in 1965 when the president of the company beckoned him into his office.

The room “was big, with a huge desk,” Marvin Fenster recalled, gesturing toward his own desk, “like this one.”

“And he said to me, ‘Kid, you’ll never make any money in retail. Try wholesale.’ ”

That’s just what the Fensters did. Instead of selling butcher wrap and other paper supplies just to small grocery stores, Marfred began buying supplies in bulk from big manufacturers and selling to small distributors at higher profits.

More Evolution

The evolution of the business, however, didn’t end with the switch to wholesale trade. Marfred also has gotten into the distribution of office supplies and the manufacturing of all kinds of packaging--from corrugated shipping boxes to display packages for stores.

In fact, it has diversified more than many competitors in its size range, said Charles J. Huck, editor of Boxboard Containers, a Chicago-based trade magazine. Marfred sells transparent tape, cardboard dividers, cellophane stretch wrap and steel strapping as well as mops, buckets and odds-and-ends like aspirin and coin-operated tampon dispensers.

“We’re a one-stop shop,” proclaimed David Jackson, director of marketing and sales. He said Marfred aims to be the “Sears of the packaging business.” Jackson said his clients, mostly small companies, “don’t have the time” to shop for supplies. “They want to run their businesses.”

The distribution end of the business brings in a hefty share of sales, Jackson said. But box manufacturing, which Marfred began just three years ago, offers fatter profit margins.

Jackson said Marfred’s recent $8-million investment in its corrugated box plant, completed in December, is evidence of the company’s continued push into manufacturing. He said Marfred bought state-of-the-art equipment imported from France.

The machinery stamps, folds, cuts and glues sheets of cardboard into flat pieces that can be folded into boxes. Bundles of the flattened boxes are shipped out of the plant, bound and covered with plastic, in packages of 25.

Dwarfed by Giants

Despite doubling its sales over the last five years, Marfred is dwarfed by industry giants such as Weyerhaeuser, Georgia Pacific and Container Corp. of America--some of the biggest companies in the paper business, which also have packaging divisions.

It is one of about 700 U.S. companies that make cardboard boxes, said Larry Lynch, director of the National Paper Box and Packaging Assn. in Haddonfield, N.J. Most small box companies, Lynch said, are regionally based. Marfred operates exclusively in Southern California, with many of its customers in the San Fernando Valley.

Lynch said the huge paper companies have other big advantages over relatively small companies like Marfred and even medium-sized companies like Unisource in Long Beach and Kent Landsberg in Montebello. For starters, they can cut costs by making boxes from their own trees. Big companies also are able to take the largest orders.

Like many companies of its size, Marfred is a family business. The company is named after Marvin Fenster and his brother Fred, 42, vice president for operations. Their brother-in-law, Jerry Weissman, is vice president for sales. Rubin Fenster, at 75, now is a full-time salesman.

Ownership of the firm is divided among them and Barry A. Ridel, vice president for manufacturing and finance, who holds a smaller share than the rest. The company won’t reveal much else about its finances.

But the Fensters are happy to discuss their business and family history. Marvin Fenster likes to point out the 1940s-vintage photograph behind his desk showing his father’s grocery in Harlem.

“We didn’t have it easy,” he said. “We didn’t go to college.”

Moved From New York

Rubin Fenster moved his family from New York to Southern California in 1955, and opened the grocery in Glendale. When Marvin Fenster started working for the business full-time 21 years ago, he was earning $60 a week.

Now the next generation is in on the act, and making better money, Marvin Fenster said. Fred Fenster’s 20-year-old daughter, Lisa, as well as Marvin Fenster’s children, Stacy, 19, and Marc, 17, all work for the company. Of the three, only Stacy works full time.

The business has grown to 250 employees, including 50 in a North Hollywood folding-carton division and another 60 at the company’s corrugated box plant in Lakeview Terrace. About 100 work at the Sun Valley headquarters, and the company also has a sales office in Orange.

R&D; Expenditures

Jackson said Marfred spends $100,000 a year on research and development for its container division, which makes storage tubes, file boxes and other products. The researchers’ work includes “drop testing” boxes to determine their weight capacity.

The company employs six full-time staffers to help customers decide how to decorate the retail packages Marfred makes that are displayed in store shelves.

Marfred designs and makes boxes for clients that include a stereo-equipment manufacturer, a Chinese-food maker, a hair-care company and a vitamin firm. Jackson said many new companies that lack marketing savvy save package planning for last.

“They don’t realize that packages make or break a product . . . that people won’t go near something if the box doesn’t appeal to them,” Jackson said.

More to Read

Inside the business of entertainment

The Wide Shot brings you news, analysis and insights on everything from streaming wars to production — and what it all means for the future.

You may occasionally receive promotional content from the Los Angeles Times.