Douglas Wins Orders for $11 Billion in Jets : Record-Breaking Pacts for Commercial Planes Will Add 5,000 Jobs This Year in Long Beach

- Share via

McDonnell Douglas announced that it sold nearly $11 billion worth of commercial jetliners Tuesday, substantially more than was expected, and as a result will add 5,000 jobs this year at its Douglas Aircraft unit in Long Beach.

The orders and options for MD-11 and MD-80 passenger jets, booked from five airlines around the world, including American Airlines, marks the largest one-day sale in aircraft industry history and increases Douglas’ backlog to $61 billion in firm orders and various types of options.

The company is so heavily loaded with aircraft orders that some of the planes are not scheduled to be delivered until the end of the century, and production is completely sold out until 1993, Douglas Aircraft President James E. Worsham said Tuesday.

In addition, Worsham disclosed in an interview in New York that orders for another 15 MD-11 jumbo jets worth $1.6 billion will be formally announced soon from three airlines in China. He declined to further identify the carriers.

“We are just very pleased with the acceptance of the airplane (MD-11) now,” Douglas Senior Vice President William Gross said in a telephone interview. “But it took us longer to get acceptance of the MD-11 aircraft, especially in this country, than we had anticipated, having launched the program way back in December, 1986.”

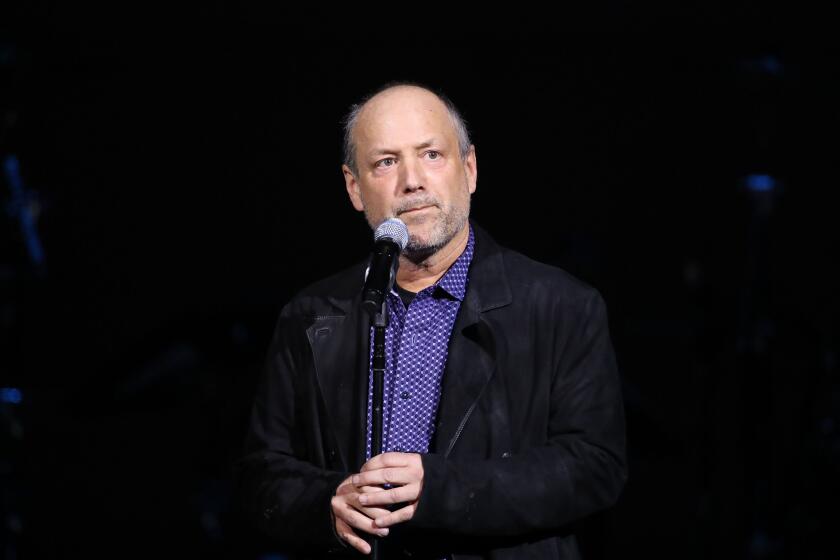

American Airlines Chairman Robert L. Crandall said the carrier’s purchases will provide for future route expansion and for replacement of some of the company’s “older and noisier aircraft.” American already has one of the youngest fleets in the industry.

Crandall said one important factor in selecting Douglas over Boeing was American’s requirement for early deliveries. Boeing is backlogged on deliveries for its 747 jumbo jet and has encountered production problems that have led to delays. American obtained early delivery dates by assuming production slots previously held by British Caledonian, which gave them up after being acquired by British Airways.

“One of the things that weighed most heavily is the great flexibility of this (MD-11) aircraft,” Crandall said. “It is a smaller aircraft than the 747-400 and thus can be used in a wider range of applications than can a larger aircraft.” However, the MD-11, which has not yet entered service, has a range of up to 8,039 miles, depending on its configuration, and will be capable of trans-Pacific and trans-Atlantic flights.

The 5,000 additional jobs in Long Beach will bring Douglas’ total employment to 45,000 at its facilities in Torrance and Long Beach, which is the nation’s largest aerospace production site. In 1981, when Douglas was on the verge of quitting commercial aircraft production, the company hit a low point of only 12,000 employees in Long Beach and Torrance.

Through a lucky combination of a boom in the commercial aircraft market and a deft plan for offering updated versions of its veteran airliner types, the company has returned to profitability after suffering through years of losses.

The sales agreements announced Tuesday included 76 firm orders and options by five airlines for MD-11 aircraft, which cost about $110 million. American Airlines signed commitments for 50 MD-11s, Air Europe for 18, Aero Lloyd in West Germany for four, ZAS Airline of Egypt for two and Finnair for two. Firm orders cover 19 of the aircraft and options account for the other 57, Worsham said.

American also placed options for 100 MD-80 aircraft, which cost about $25 million each. Those aircraft would be delivered between 1992 and 1996.

Although such a large proportion of the planes involve options, rather than firm orders, financial analysts were upbeat about McDonnell Douglas’ prospects. With a firm order, an airline typically must make a down payment of 10% of the value of the plane, whereas an option requires only a 1% down payment and is more easily cancelable.

“They are all good, firm orders, as long as the economy holds up,” said Prudential Bache Securities analyst Paul Nisbet.

Nisbet said investors had originally viewed the MD-11 as a “probable failure” but have begrudgingly changed that outlook to one of “optimism.”

McDonnell Douglas stock gained 87.5 cents per share to close at $89 Tuesday in trading on the New York Stock Exchange. On Jan. 13, the week before speculation arose about the American Airlines deal, the company closed trading at $79.50 per share. Over the three-week period, the stock has gained nearly 12% in value.

The first MD-11, which is a derivative of McDonnell Douglas’ DC-10 wide-body airliner, is expected to make its first flight in May and be certified for delivery by the Federal Aviation Administration by spring of next year. The aircraft, which has three engines and travels at speeds of up to 588 miles per hour, is designed to carry up to 405 passengers. However, the American MD-11s will be configured to carry only 245 to 274 passengers.

McDonnell Douglas is carrying orders and options for 253 MD-11s, putting the company substantially ahead of the A-340, a competing jet built by Airbus Industrie, the European aircraft manufacturing consortium.

“It’s too early to say Douglas has won the competition against Airbus,” Nisbet said. But he added, “Certainly, McDonnell Douglas has nosed ahead in the early competition.”

McDonnell Douglas also announced Tuesday that Rolls-Royce of Britain will begin to offer jet engines for the MD-11, which is expected to help politically in efforts to market the airliner in Europe.

American Airlines also announced that it will buy 200 General Electric jet engines, worth about $2 billion, in addition to those that will come installed on the new McDonnell Douglas airliners. The engines will be used as spares and for installation on planes that American plans to obtain from other manufacturers, a GE spokesman said.

Although Douglas has grown far beyond projections of only a year ago, it is encountering capacity problems in Long Beach, said Gross.

Bigger and more complex aircraft are taking up more space at the facility and making it more difficult to increase production rates. Douglas produces 2.5 MD-80s per week and plans to produce one MD-11 per week.

The company will employ 16,000 workers on the MD-11 alone, Worsham said.

Gross said the company is studying three options that would enable it to increase MD-11 production beyond the current plan of one a week. One of the three options would involve moving the entire MD-11 line out of Long Beach. But that “is only a study,” he said.

In addition, Douglas encountered significant problems last year when it fell behind schedule and failed to meet delivery deadlines on orders by a number of customers. Those delays are not getting any worse, but Douglas will not be back on its original schedule until early to middle 1990, Gross said.

“We were very unhappy with McDonnell Douglas,” American’s Crandall said Tuesday about the delay. “They have gotten that problem under control. . . . They have been delivering planes right on schedule and very high quality.”

But increasing the output of aircraft will be difficult even if Douglas can ease its internal constraints. Aircraft parts vendors, which supply 60% to 80% of the parts Douglas uses, are encountering capacity problems themselves.

The multibillion-dollar aircraft orders being announced by Douglas and Boeing are having huge ripple effects throughout the Los Angeles basin, the biggest aircraft parts production center in the country.

For example, M.C. Gill Corp., a family-owned El Monte aircraft parts producer, will be increasing its 170-member work force by more than 30% this year, principally due to MD-11 work from Douglas, President Stephen Gill said Tuesday.

Ralph Vartabedian reported from Los Angeles and Robert E. Dallos from New York.

More to Read

Inside the business of entertainment

The Wide Shot brings you news, analysis and insights on everything from streaming wars to production — and what it all means for the future.

You may occasionally receive promotional content from the Los Angeles Times.