GM AND THE JUICEMOBILE : To Satisfy California’s Tough Anti-Smog Laws, General Motors Jumped on the Electric-Car Bandwagon. But Can the Wounded Giant Follow Through With a Car We’ll Want to Buy?

- Share via

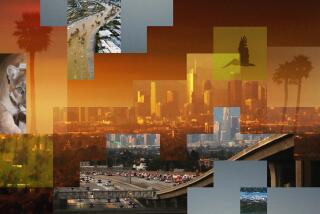

COMPETITION FOR THE EYE OF CAR-SAVVY CALIFORNIANS WAS INTENSE THAT JANUARY WEEKEND in 1990. Amid the flashing neon and leggy models at the Los Angeles Auto Show, all the world’s manufacturers had paraded out a stream of futuristic concept cars. * There was a snazzy Porsche fastback powered by a gutsy 250-horsepower engine. A speedster with wet-suit upholstery that could be hosed out after a trip to the beach. A topless beach car with a radio that doubled as a portable boombox. A sedan equipped with video cameras instead of rearview mirrors. * But none attracted the crowds like the unassuming silver coupe displayed under the blue-and-white General Motors logo. Eager for a look at the car named the Impact, auto show patrons lined up around the velvet ropes. How much is it? How fast does it go? Does it really work? When can I buy it? * John Williams was amazed by the reaction. The then-manager of advanced engineering at GM’s Chevrolet-Pontiac-Canada group had flown in from Detroit to gauge the public’s interest. He had never before seen the Impact, but as he boarded the jet for Los Angeles he thought, “No big deal. Just another concept car.” In his 25 years at General Motors, Williams, then 42, had seen many such cars come and go, and he knew most were just fantasy machines for repressed engineers. * Williams and his colleagues had become almost numb to the ridicule of Californians who think GM stands for Generally Mediocre. Walking past all the Hondas, Toyotas and BMWs in the convention center’s parking lot, he was painfully reminded that the ailing, stodgy old man of the auto industry has one of its smallest market shares--24%--in California, the car capital of the world. * Yet, to his surprise, here was a GM prototype that had captured the imagination of this discerning crowd. The Impact, a two-seater with a sleek teardrop shape, fascinated people not for the amenities it had, but for what it didn’t have: no engine. No fuel. No exhaust. No transmission. No muffler. And it would never need a tuneup or a smog check.

To satisfy his own curiosity, Williams pored over the car’s engineering specs. He learned that the simple little car had broken one longstanding technology barrier after another, from its horsepower to its battery range. The more he read, the more he wondered: Had the electric car finally come of age?

Three months later, in celebration of the 20th anniversary of Earth Day, Roger Smith, then-chairman of the automotive giant, made an announcement that startled the global automobile industry. General Motors vowed that the first mass-produced electric cars would roll off its assembly lines by the mid-1990s, with the inaugural batches headed for smoggy Southern California.

MANY PEOPLE--INCLUDING SOME WITHIN ITS OWN CORPORATE RANKS--WONDER WHAT KIND OF insanity has gripped the world’s No. 1 auto maker. The prototype, the Impact, wasn’t even conceived or built by GM’s own staff but by a bunch of mavericks in the San Gabriel Valley who had never made a real car before. Why would General Motors, notorious for its ultraconservatism, invest tens of millions of dollars--eventually hundreds of millions--in an electric vehicle at the same time it was suffering its worst corporate losses in history? Its electric-vehicle team has remained virtually unscathed in the midst of a fiscal rampage in which GM plans to shut down 21 plants and eliminate 74,000 jobs to try to recover from its $4.5-billion 1991 loss.

Yet the decision wasn’t really so rash. The stakes in the electric-car business rose when, in September, 1990, California adopted the world’s toughest automobile-emissions standards. Beginning in 1998, 2% of all major manufacturers’ cars sold in California (or about 40,000 cars) must be emissions-free, increasing to 10% by 2003. Auto makers have a strong incentive to make the electric cars efficient and priced to sell; if they fail to meet the mandates, they will be prohibited from selling any cars in California.

At GM’s sprawling, campuslike Tech Center in the Detroit suburb of Warren, a high-spirited but anxious team of more than 200 men and women is racing to meet the company’s goal of being first to market. Other auto manufacturers around the world are now rushing to catch up, most keeping their progress a closely guarded secret. So far, Ford and Chrysler are concentrating their electric-car efforts on vans, to be marketed to businesses that operate fleets of cars.

The GM team is wrestling with engineering challenges entirely new to the auto industry as it prepares to manufacture its electric cars at a shut-down Buick plant in Lansing, Mich. The team members are busily fine-tuning such quirky details as how to display the amount of battery power available, where to bolt the front license plate so it doesn’t spoil the crucial aerodynamics and how to minimize the crunch of the tires on gravel since the car runs silently, with no engine to mask outside sound.

And they are pondering what may be the most puzzling unknown of all: Who will buy a car that travels only 120 miles on a charge and needs its $1,500 battery pack replaced every 20,000 miles? It wouldn’t make it halfway from Los Angeles to Vegas before the owner would have to pull up to an electric outlet and recharge its battery for eight hours.

While electric cars have been made for years by small businesses and garage tinkerers, no major auto company has made one from scratch, then mass-produced it. Some GM executives harbor fears that consumers will dismiss it like some novelty in a Sharper Image catalogue. The price of the car is a big question mark. New York auto-industry analyst Mary Ann Keller says Southern Californians are practical about their disposable income. “These are not cheap vehicles to buy or own,” Keller says. “The number of people who will do things because they want to preserve the environment is very, very small.” If Californians must choose between a face lift or a smog-free car, she says, they’ll keep their Honda Accord and take the plastic surgery, even if it wouldn’t help save the planet.

Amy Rader, who is designing GM’s electric-car advertising strategy, acknowledges that “there are a zillion reasons why this shouldn’t work, why the market will be slow to accept it. It’s a new technology, and people have a billion questions. But we’ve got this breakthrough electric-vehicle prototype, and it’s sort of like somebody giving you a ticket to the lottery and saying, ‘This may or may not be the winning number. Do you want it?’ How could you not?

“Let’s face it,” she adds. “There are things at GM that used to work that don’t work anymore. GM may be big and conservative, but it’s not stupid. It sees a profit opportunity here and sees that it is probably the only one with all the resources to pull something like this off. For us, it’s a moon-shot.”

THE BRAINSTORM BEHIND THE IMPACT CAME ON A FRIDAY AFTERNOON IN NOVEMBER, 1987, AS Alec Brooks, a Pasadena engineer, stood in the winner’s circle in Adelaide, Australia. The Sunraycer, a solar car built by Brooks and a team of engineers and consultants sponsored by GM, had just set a record in the World Solar Challenge by skimming 2,000 miles across the continent on no more power than a hairdryer’s. Never had an alternative-energy car gone so far, so fast.

After the triumphant win, Brooks and others toured the United States with the Sunraycer, and people everywhere asked him the same question--when will the major auto companies make pollution-free cars? That question was like posing a dare to Brooks and his colleagues at AeroVironment Inc., a tiny Monrovia firm of free-thinking inventors.

Raised in smog-shrouded Altadena, Brooks knew California was mounting a renewed campaign to clean the air in the Los Angeles Basin, where the biggest culprit is car exhaust. He was certain the lessons he learned from the Sunraycer about streamlined aerodynamics and ultra-efficient power electronics could be used to build a battery-powered car that people would want to drive--one with guts, with the range, power and speed to survive L.A. freeways. But he needed the backing of a major auto maker. His first choice was the world’s largest, General Motors.

Brooks’ mentor and boss, AeroVironment chairman Paul MacCready, had longtime Caltech alumni ties with executives at Hughes Aircraft, which GM had purchased in 1986. So Brooks hooked up with Howard Wilson, an amiable, creative Hughes vice president who had guided the Sunraycer project. Wilson, nearing retirement at the time, was renowned for conjuring up seemingly outlandish projects and cheerfully persuading people to back them. He also had the ear of GM management, since he served as liaison between high-tech research at Hughes and the parent company.

In the summer of 1988, Brooks and Wilson flew to Detroit and passed through the vault-like double doors of General Motors’ palatial headquarters. There, in the womb of an institution nicknamed Mother Motors, they planted the seeds. Less than 18 months later, the Impact was born.

IN ITS EARLY STAGES, WHEN ONLY A HANDFUL OF PEOPLE IN CALIFORNIA AND DETROIT KNEW what the engineers were up to, the experiment was known as Project Santana, aptly named for the Santa Ana winds that blow smog out of Los Angeles. The name might also have foreshadowed the heated emotions that would surface during the design and production process. Creating an innovative car was relatively easy, it turned out; changing the way GM worked was the real challenge.

The GM project was a coup for AeroVironment, the small but highly regarded team of engineers headed by MacCready, an internationally renowned inventor. He and his staff had already pioneered an impractical but impressive lineage of lightweight, fuel-free vehicles, including the Gossamer Condor, the world’s first human-powered aircraft.

“This was a new thing for AeroVironment. We had never built a car other than Sunraycer, and this was very different,” says Brooks. “It was meant to look like a real car, with regular doors and air conditioning and windows that go up and down. So it was hugely more complex than the Sunraycer.”

The electric car’s time had come--and gone--several times before. The first ones, driven by this generation’s great-grandparents before the turn of the century, were hampered by low speeds and limited range. They were outpaced by rapid advances in internal-combustion engines, and gasoline quickly displaced batteries in powering automobiles. Still, every decade or so, curious engineers in Detroit would begin tinkering with electric cars again, usually when an overseas oil crisis loomed. Every time, the projects failed. The cars were slow and clumsy, like golf carts. Their batteries were too heavy, too weak and too expensive.

Not wanting to repeat those mistakes, Brooks and Wilson did their homework. They were so self-assured about breaking every technological barrier that GM’s executives broke precedent and approved a demonstration project by this outside company within weeks. Brooks’ deadline was Dec. 15, 1989--less than 1 1/2 years to design and build a completely new type of car. GM wanted the experimental car for the Jan. 4, 1990, auto show in Los Angeles.

As manager and chief engineer of Project Santana, Brooks brought to his engineering team many alumni from his alma mater of Caltech rather than the usual East Coast-MIT clan that dominates GM. Meticulous, intense and confident, Brooks, 37, is known for breaking convention. One executive at GM (which recently bought 15% of AeroVironment) calls Brooks the “Thomas Edison of today--you just wait and see.”

When Brooks enrolled at Caltech to get his doctorate, he chose the conservative field of civil engineering, just like his dad. Soon, though, Brooks realized his real interests were cars and airplanes. He joined AeroVironment in 1981; on his own time, he and a partner designed and constructed the record-breaking, human-powered Flying Fish, a boat pedaled on water like a bicycle.

To an engineer, simple is elegant, and that was Brooks’ ultimate vision for Project Santana. He wanted a sporty two-seater that could reach 60 m.p.h. in eight seconds--faster than 98% of the cars on the road. Its battery must last 120 miles without charging, and it must have at least 110 horsepower. None of these milestones had ever been achieved in one vehicle before. No one had even come close.

The biggest challenge for Brooks’ team of 20 engineers and technicians was to create a powerful, quick car yet keep the weight down, since the batteries alone weigh 900 pounds, more than one-third the total weight of a traditional car. They had to craft a battery, electronics system and motors that would create the accelerating power of a gasoline-driven sports car yet remain lightweight and compact.

Free-lance electronics whiz Alan Cocconi’s mission was to fashion the heart of the car, its inverter, which delivers the battery’s current to the motors that run the wheels. An opinionated Caltech alumnus with a rapid-fire mind that thinks in 3-D, Cocconi was known for working fast--he had developed the concept for the Sunraycer’s electronics system in three weeks. Within two months, he had designed a key element for the Impact that would switch the battery’s DC current to AC, which was needed to run the motors. Within 16 months, he had taken almost 300 of the most sophisticated semiconductor chips available, linked them together like a high-tech jigsaw puzzle and tediously hand-soldered thousands of joints, creating a compact package about the size of a suitcase.

Cocconi wound up with an electronic controller that put out more than 100 kilowatts--enough to deliver power to 25 houses on a hot summer day--yet weighs only 61 pounds. Nobody before had made one so powerful.

At the same time, Wally Rippel, then at NASA’s Jet Propulsion Lab in Pasadena, used his spare time to help design the power train--which links the battery, motors and the electronics system that delivers the current. To get the acceleration Brooks wanted, the two motors--one for each front wheel--must spin rapidly. Rippel decided to drive the motors with alternating current and use a brushless design that eliminates friction. The result: a peppy 114 horsepower--the equivalent of a sporty Honda.

GM’s battery branch, Delco Remy, simultaneously went to work on the power source, wrapping together 32 10-volt batteries in a single pack that was made ultra-flat by keeping the connections between cells paper-thin. Because the technology was easy and cheap to mass-produce, they chose lead-acid--the chemistry found in traditional car batteries--even though exotic, experimental types, such as sodium-sulfur, produce more energy. The 900-pound pack fits between the seats, forming an armrest as well as the central backbone of the car. To create less drag, a team from Goodyear specially crafted high-pressure tires inflated to 65 psi--about twice as much as standard tires.

As Brooks and his team hurriedly custom-built one new component after another, a separate team at GM’s Advanced Concepts Center in Thousand Oaks worked on creating the car’s overall look. That’s where the conflict began.

THE GM DESIGN CENTER IS PURPOSELY LOCATED 2,500 MILES FROM DETROIT TO keep the creators thinking freely. The more bizarre the car, the better, in their eyes. And true to form, the 20-member Project Santana design team, headed by John Schinella, came up with some far-fetched ideas. They first designed a car with wheels in giant pods protruding from the sides--an exaggerated feature they thought would cry out “vehicle of the future.”

Brooks, however, insisted that nothing could compromise the car’s aerodynamics. He also wanted a car that looked, well, normal, to ease the public’s fears of the new technology. “There was a little attitude (among the engineers) of, ‘We don’t care what it looks like as long as it works,’ ” Schinella says. “We said, ‘No, beauty must be in our eyes.’ ”

The designers and the engineers bickered for a while, neither side giving in, losing precious time. Finally, the word came down from Detroit: Settle your differences now.

Schinella’s designers returned to Caltech’s wind tunnel countless times, sculpting dozens of different shapes, from a snout-nosed design to a fastback. Finally, the designers pushed the widest part of the car to the front, winding up with an aerodynamic teardrop shape that pleased both the engineers and the designers.

A large, flat table, crisscrossed with grid lines, was laid across the floor at an AeroVironment shop. The fiberglass frame was built from the bottom up, every part handfitted. Each bit of assembly was troublesome. The windshields wouldn’t fit, and new ones were Federal Expressed back and forth across the country. Finally, eight weeks before the auto show, the shell of the car was delivered to a frantic Brooks in Monrovia to install the wiring and electronics.

“When this car came to us it was unpainted, it was raw fiberglass,” Brooks says. “We worked for a month solid, without any breaks.” Some members of Brooks’ team were losing confidence that the Dec. 15 goal would be met.

Two weeks before deadline, Brooks and his team hid the car in a trailer and hauled it a few miles to the empty parking lot of the Santa Anita Race Track. They needed a road test to make sure the wheels turned and the brakes worked.

The car was far from fit for the road. It still had no doors or windows, and it was the awful green of raw fiberglass. When Brooks started it up in the parking lot, there was no ignition, no rumbling engine. The car moved silently and smoothly as if powered by nothing at all. When he stepped hard on the accelerator, the car took off so fast that he could smell burning rubber. When he lifted his foot, the energy fed back into the battery, stopping the car smoothly without using the brakes. Exhilarated, the crew took turns zipping around the parking lot.

Testing the vehicle’s true limits, however, came a few days later, at the GM Proving Grounds in the desert outside Mesa, Ariz. The first results were disheartening. The batteries lasted a mere 70 miles at freeway speeds before needing a recharge. It turned out that too much oil was sloshing around in the gearbox and motors.

The final test came on Dec. 10--five days before the deadline--in the desert. The result was 124 miles of battery range with start-and-stop city driving and acceleration from zero to 60 m.p.h. in 7.9 seconds--faster than a Miata or a Nissan 300ZX.

Brooks was ecstatic. Everything he dreamed about, everything he had promised to GM, had proven possible. But his joy was tempered by a rush of fear. The car was still a blotchy green mess, and the auto show was just three days away.

“We took it to the paint shop at 4 o’clock in the afternoon, and they went to town on it. They sanded it, working late into the evening. Early the next morning, they sprayed silver paint on the car,” Brooks says. “It was transformed.”

Back in California, cushy gray seats were installed and the paint job finished, with the team working on the car up until the very morning it was unveiled in Los Angeles.

Early in December, somebody in Detroit--nobody recalls who--had come up with a name to symbolize what they all hoped the car would have: an Impact.

On the morning of Jan. 3, 1990, the press gathered at Hughes Aircraft’s headquarters, in the shadow of Los Angeles International Airport. Brooks met in Hughes’ garage with then-GM Chairman Roger Smith, giving the top executive--who had never seen the Impact--a quick lesson in driving it. Brooks, who since has gone on to design another top-secret car project for GM, then turned the keys over to Smith with the mixture of Angst and pride of a parent at the wedding of his favorite child.

Project Santana was officially over.

AT HIS HOME IN LAKE ORION, NORTH OF DETROIT, JOHN WILLIAMS WAS WATCHing “The Tonight Show” when Johnny Carson poked fun at GM’s new electric car. It was the day after the unveiling of the Impact, and Carson quipped, “What’s next? The Ford Whiplash?”

Williams didn’t think it was all that funny. In fact, he was a bit irked; he thought American car makers, with all their troubles, needed support, not ridicule. But more than anything, he was shocked: Like many other GM employees, Williams first heard the news of the electric car from Carson’s late-night monologue.

“There I was, working in GM’s advanced projects, and I didn’t even know it was going on,” Williams says. Two days later, Williams flew off to Los Angeles to watch the Impact become the star of the auto show. When he returned to Detroit, General Motors had a decision to make: Should it really manufacture this car?

Headed by Williams, a feasibility team of 15 engineers, finance managers and marketing experts sequestered themselves for two months in a conference room in Detroit. They were charged with determining if it was possible to turn the hand-built prototype into a profitable mass-produced car.

Two outsiders, Bob Wragg and Bob Cross, remember it was like being thrown into a room full of people who all spoke different languages. Wragg and Cross, straightshooting, outspoken Hughes Aircraft engineers from Los Angeles, were brought in by GM to help the company learn more about systems engineering. The approach--breaking a complex project into individual tasks that all fit together in the end--was mastered by the aerospace industry in the ‘50s but had never caught on at GM.

General Motors is notorious for making top-down decisions that leave the poor stiffs who build a car with the impossible job of making it all work. It showed, Cross thought, in how slowly the company designed a new car. What takes other companies four years takes GM six or even eight. Wragg and Cross had heard about the infamous partitioning of GM: The Buick guy knew Buicks. The battery guy knew batteries. The marketing guy knew what sells. Each had his little empire, but none knew the whole picture behind a car, and none seemed to understand the others’ missions.

The first thing Wragg and Cross did was persuade the GM team to discard everything they knew about making cars. They told the team to pick the process apart and come up with new, more efficient ways to streamline engineering, manufacturing and marketing, which triggered a lot of infighting in the first few weeks.

After months of discussion, the team issued a slim report concluding that the Impact might not make money for GM at first but would open up an emerging market, pave the way for future technology, help wean the nation off foreign oil and give the company a new environmental image.

“Getting GM’s management to turn this into a production program would be quite a leap of faith. I knew enough about GM to be wary of that,” says Wragg, who now is California market-development manager of the electric-vehicle team. “It had two big obstacles--acceptance by GM’s conservative management and acceptance by the public.”

Williams took the recommendation to the top on April 10, 1990. He met with two of the company’s top executives, Bob Stempel and Lloyd Reuss. (Stempel took over the top position as GM’s chairman when Roger Smith retired in August, 1990. Reuss was promoted to president, then demoted this year to executive vice president in a shakeup triggered by GM’s severe financial troubles.) “There are no guarantees,” Williams told them. “Maybe it will be a big bomb.”

Things were looking incredibly bad for the car industry, especially GM. The company was suffering unprecedented losses. When times are tough, there are two streams of thought among corporate presidents. One is to lie low, be cautious. The other is to do something nervy to break out from the crowd.

Roger Smith had already been bombarded with bad publicity--including the irreverent “Roger and Me” film that painted him as a corporate ogre. He has a notorious ego, and he wasn’t the type to retire without being remembered for something gutsy. He also had a passion for technology. He took the leap.

On the morning of April 18, 1990, Alec Brooks drove the Impact down public streets for the first time, toward Washington’s National Press Club. There, Smith declared that GM would mass-produce the Impact by the mid-1990s. Now, the real work would begin.

Williams remembers being a bit unnerved by the announcement. Now head of program management of GM’s electric-vehicle team, he says, “The difference between being courageous and being foolish is a very fine line.”

WHEN KEN BAKER WAS CALLED to GM headquarters in the spring of 1990 and offered the job of leading the team that would produce the Impact, it jogged unpleasant memories of 10 years earlier. A mechanical engineer, Baker, 45, joined GM in 1969, when he was just 22--a relationship that has lasted as long as his marriage. He headed the team that tried to produce the Electrovette--a metamorphosed Chevette that was GM’s last electric-car project--and he vividly recalls the day he took a GM vice president for a test ride and the transmission got stuck. He had to walk a mile and a half back to the office with the surly VP, who scolded him the entire time. The project never made it into showrooms.

But Baker wanted to try again and do it right this time, starting with a handpicked staff. In the beginning, there were only three on the new EV team--Baker, Williams and Baker’s executive secretary, Shirley Plumb. Plumb is a maternal woman who, in 35 years at General Motors, has tutored many young engineering executives--”my puppies,” she calls them--as they climbed the corporate ladder. She remembers how some resisted when Baker recruited their best people for the Impact team.

Before joining the risky start-up team, many corporate veterans had comfortable, 20-year careers at GM. Others were bright but inexperienced. Baker chose people who would take chances, who were fond of firsts.

When Randy Schwarz got Baker’s phone call at home one evening asking him to become director of manufacturing for electric vehicles, he and his wife and three children were packing for Tokyo. Schwarz had just accepted a three-year assignment to direct GM’s manufacturing in Japan. The moving van would be at his house in two days. He chose the Impact team with no hesitation.

Once Baker assembled his eight top executives, one of his first ideas was to immerse them in the culture of Southern California. They took to the streets of Los Angeles, some for the first time, to see for themselves what Californians want in a car. It was a hard dose of reality for Detroit’s engineers to learn that the location of the dry-cleaning hook was just as important to some car owners as the efficiency of an engine.

The executives also braved the freeways on a mad scavenger hunt--orchestrated by a fiendish GM marketing type--in search of a few California-only tokens. Sand from Venice Beach. A photo of the world’s largest car dealership--Longo Toyota. A chunk of grass from the Coliseum. All nine executives returned to Detroit understanding how a seven-mile commute could take 40 minutes.

Baker replaced the old GM management style with the mixed-discipline approach preferred by the Japanese. When GM normally designs a new car, the project moves slowly from the design staff to the engineering staff and finally to manufacturing and marketing, each group housed in a separate building as impenetrable to the others as a fortress. At the conclusion of each step, the car is “thrown over the wall” to the next group.

Baker wanted each team to have input from the beginning so that GM didn’t wind up with an electric car it couldn’t manufacture or, worse yet, couldn’t sell. He threw the entire team together, working side-by-side on the third floor of the no-frills engineering building at the mile-square Tech Center.

It was either a stroke of genius or a stroke of sadism. Engineers always think they have created a masterpiece and that it’s the klutzes on the assembly line who can’t make it work. Manufacturing teams think engineers are self-absorbed tinkerers who come up with unworkable ideas. And the marketing people are pariahs to both. One staffer says the Impact team is like a United Nations program, with everyone learning a new culture. For many GM veterans, it’s meant culture shock. Slowly, engineers are picking up marketing jargon, asking, “Will the dog eat the dog food?” And marketing people are starting to sound like engineers when they discuss “driver-vehicle interface.”

At a time when GM is struggling, the team exudes energy and confidence. Walk down a flight of stairs to another floor, where engineers are designing conventional cars, and it seems virtually empty, smothered by a pall of fear about job security. But on the third floor, the workers are noisy, active and unusually youthful for GM. Engineers sit in a darkened room, their faces bathed in eerie white light. They refine the car’s components on their computers, changing the seat angle, digitizing the dimensions of a new tool, simulating crashes at every possible position.

In the mock-up room, where hoods and bumpers and trunks are shaped in cardboard and wood, each engineer works on a separate piece of the car. There’s even a wood mock-up of the trunk, and the team members use simulated bags of golf clubs and groceries to see if they fit. For a while, the designers considered putting no hood on the car. They liked the idea of a seamless front, but the marketing folks told them it was “too strange,” since people like to look under the hood even if there is no engine to tinker with.

The team’s ultimate goal is to simplify the Impact’s design and keep the weight down while still giving drivers amenities. The team worries that, with each revision, the car is getting heavier. The prototype was not developed to be crashworthy, so the car must be lightened by several hundred pounds to accommodate safety equipment.

“To make this car work,” Williams says, “it has to be very lightweight. If you screw anything up, even just a little bit, you’ve got big problems with your 120 miles of range. You can lose 20 miles just like that,” he says, snapping his fingers.

TODAY, THE RACE CONTINUES to “drive out all the inefficiencies,” as Williams puts it. Although onlookers say 1994 or 1995 is the most likely debut year, the EV team members won’t disclose how close they are to the assembly line. They worry that they have foolishly revealed too many secrets to the competition in their zeal to publicize the concept car’s breakthroughs.

The EV employees know that management could dump the program anytime. But it’s unlikely, they say, since the manufacturing plants were recently announced--one in Lansing to assemble the car, two in Indiana to make the batteries and motors and a Hughes plant in Torrance to produce the electronics. Anything’s possible, though, when a company is in financial upheaval. “The only time you’ll really know,” Williams says, “is when I call you up and say, ‘Hey, there’s one down in the showroom.’ ”

Auto-industry analyst Mary Ann Keller reflects the beliefs of many critics who find the Impact program a foolhardy venture. She sees electric cars as expensive and impractical and thinks it will take a government subsidy or tax rebate to persuade people to buy them. GM refuses to divulge the expected price, saying only that it will be competitive with similar gasoline-powered cars, such as Mazda’s Miata or the Honda CRX. GM’s top-secret 1990 study shows that the feasibility team estimated the price at $16,800.

“GM may put out a state-of-the-art electric car with some really good technology, but it’s going to be expensive, and the market will be limited,” says Ken Koch of KTA Services, an Orange County company that produces kits for people converting traditional cars to electric-powered ones. Koch predicts the eventual price of the GM car will be closer to $40,000.

Some experts also doubt whether GM has the skills to pull this off, since the company isn’t known for superior technology or efficient manufacturing. Even some of the consultants who helped design the Impact are now wondering if the technology will be so altered by GM that it will be inefficient. Keller believes GM has gone wrong in selecting a sporty two-seater instead of a more practical van.

Amy Rader, the EV team’s advertising manager, often hears such skepticism. She takes comfort in reading about similar beliefs that plagued the car industry in its early days, when some critics thought automobiles were impractical substitutes for horses. Gasoline is much more expensive than hay, they said, and cars would need all new roads and a completely new infrastructure for fuel. No person in his right mind would sit atop an engine that’s basically a series of explosions. These skeptics concluded that making horseless carriages was a waste of time and money.

Rader glances out her window at the empire GM built on such a silly whim, and she smiles ironically--knowing that conventional wisdom often turns out to be just horsefeathers.