The Cutting Edge: COMPUTING / TECHNOLOGY / INNOVATION : Hamburgers--and Their Fat--Get Some Respect

- Share via

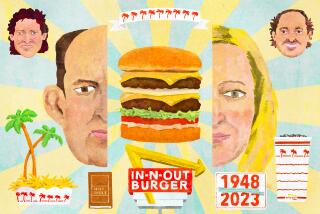

Purdue University foods and nutrition professor Martha Belury thinks that the time has come to give cheeseburgers some respect.

Ever since researchers found a relationship between dietary fat and cancer, red meat and cheese have been cast in the role of bad guys. But Belury, working out of the West Lafayette, Ind., university, has found that a polyunsaturated fatty acid called conjugated dienoic linoleic acid (CLA), found in fatty fried hamburger, actually inhibits several types of cancer in laboratory animals.

Other good sources of CLA are also foods not found at the top of the health food charts: cheese, processed cheese, milk and yogurt. And heating food, such as pan-frying meat or pasteurizing milk, actually increases the CLA content.

While most other cancer-fighting compounds that have been found in food only affect one organ, such as the stomach or skin, CLA actually protected cancer-prone mice against stomach, mammary and skin cancers. While researchers don’t know exactly how it inhibits cancer, in certain tests CLA acts as an antioxidant that stops harmful molecules known as free radicals from damaging cells in ways that could cause cancer.

Other tests suggest that CLA might selectively kill cancer cells, or that it might replace other, cancer-promoting fatty acids in the cell membrane. While these findings don’t contradict the National Cancer Institute’s recommendation that people cut down on total fat intake, it appears the occasional cheeseburger might not be all bad.

Software, Not Soft Wax: The technology known as rapid prototyping has come to be associated with the factory floor, not the operating room or the dentist’s office. But researchers are beginning to use rapid prototyping to make plastic medical models that can help doctors visualize and practice precise surgical techniques before an operation. The models not only reduce a patient’s time in surgery and the risk of complications, but can also be used to create molds for custom-fit prostheses and tailor-made dental implants.

Rapid prototyping involves the use of computer-aided design models, a laser and an optical-based fabrication system that can quickly carve out plastic parts without a mold. With specialized software, researchers can take information from CAT and MRI scans and create anatomically precise medical models in a matter of hours.

Although the technology is still in its infancy, it is beginning to be used more widely in surgical planning. And researchers from Wilford Hall Medical Center at Lackland Air Force Base in San Antonio, Tex., found that rapid prototyping can save dental technicians thousands of hours when used instead of the current method of making wax patterns for teeth and dentures--drop by hot wax drop.

More Logical Landings: How many times have you wished that the emergency lights in your car would warn you of an impending failure while there was still time to get to a service station? Most of us end up standing at the roadside waiting for a tow. And when American Airlines Flight 191 developed an engine and hydraulic system malfunction at Chicago’s O’Hare International Airport back in 1979, the problems weren’t detected in time for the pilots to save the plane, resulting in one of the worst crashes in aviation history.

Studies of the crash on a simulator have suggested that the plane could have been flown successfully despite the problems if the pilot had known about the failure of the hydraulic system in time to make the necessary adjustments in the aircraft controls. Now two electrical engineering professors at Ohio State University are developing a system that would help pilots regain control of their aircraft through the use of “fuzzy logic.” Their aim is to develop a control system that would automate pilot expertise and take action to save the aircraft as soon as an error is detected.

Fuzzy logic is a method for giving inexact operating instructions to machines. It takes into account the vagueness present in many situations, such as an emergency on an airplane. Conventional control systems are based on mathematical differential equations which are not always effective in translating the somewhat inexact human problem-solving techniques into a computer algorithm. The Ohio State researchers have tested their theories in a simulator and the results indicate a fuzzy control system might be able to adjust for various aircraft system failures.

Ouch, That Hurt!When a dentist’s probe touches an exposed nerve, most humans respond to the pain by flinching. Researchers at Sandia National Laboratories in Albuquerque, N.M., have found that defective integrated circuits will do much the same thing when zapped with a tiny electrical charge.

In the case of integrated circuits, the “flinch” is a change in voltage at the point of the defect. But just as your response to the dentist’s pick indicates a possible cavity, that voltage change tells engineers that an integrated circuit has an open conductor that will affect the reliability of the circuit.

Open conductors are microscopic cracks that break the electrical connections in integrated circuits. As these chips have become smaller and more complex, it has been harder to detect open conductors. But a new technology developed at Sandia can find the defects in minutes. The technique, called low-energy charge-induced voltage alteration (LECIVA), uses a scanning electron microscope to inject a small amount of electric charge at a precise microscopic point on an interconnection. This charge does not affect a normal circuit, but causes a voltage change at the spot of the defect which is detectable with the electron microscope.

Sandia has applied for a patent on LECIVA and hopes to license the technology.