Weak Rivets May Have Been Titanic’s Fatal Flaw

- Share via

WASHINGTON — Tim Foecke was hunched over his microscope one day last fall, peering at a rusted hunk of iron that had been sliced down the middle to reveal its silver-colored core and the pattern of its internal structure.

It was an antique ship rivet, made of Scottish iron and pounded, along with 3 million other rivets, into the White Star Line’s famous hull No. 401 in Belfast’s Harland & Wolff shipyard about 1910.

As Foecke studied the patterns of slag streaking through the metal, he saw that near one end, where the rivet head was gone, the streaks changed direction sharply--a sure sign of structural weakness. “Wow!” he murmured to himself: Hull 401 had been the Titanic.

Foecke’s discovery in September, in his tiny laboratory at the federal government’s National Institute of Standards and Technology in Gaithersburg, Md., substantially bolstered a chilling new theory about the great ship’s demise: that the vessel, the technical wonder of its day, may have had a fatal weakness in its lowly rivets.

The theory is that the wrought-iron rivets, born in the steelworks of the now-defunct D. Colvilles & Co., outside Glasgow, were structurally weak from unusual patterns and excessive amounts of the byproduct slag.

And when the 46,000-ton RMS Titanic hit the 300,000-ton iceberg off the coast of Newfoundland the night of April 14, 1912, the impact didn’t slice a 300-foot gash in its side but, rather, popped the rivets, “unzipping” seams in the hull plates in six places.

The total area open to the sea, experts now believe, may have been no bigger than a closet door.

It is the latest concept to emerge as scientists conduct a kind of ongoing mechanical autopsy of the Titanic, in the wake of its discovery in 1985 in 12,000 feet of water by oceanographer Robert Ballard.

Working with artifacts recovered from the ocean floor, videotape, photographs and special underwater imaging, Foecke and a host of metallurgists, marine architects and other experts have been seeking to piece together the exact details of the ship’s death.

That Foecke’s scholarly paper on the rivets was formally issued Feb. 10, the day the blockbuster movie “Titanic” was nominated for 14 Academy Awards, was completely coincidental, an institute spokesman said.

Indeed, Foecke, 34, of Damascus, Md., a burly 6-foot-4, 270-pound Minnesota native, said he has yet to see the film. “Partly, I don’t have the time,” he said.

But he does keep the precious rivets--for which a collector has offered $10,000--in a wooden file drawer secured with a big metal padlock. “I asked for a safe,” he joked in his book-filled office recently. “But we didn’t have the money.”

A student of history as well as metallurgy, he has become fascinated with the mystery of the Titanic’s sinking. “It’s exciting,” he said. “This has got to be one of the highest-profile metallurgical failure analyses that there are.”

He now believes that the “microstructure” of the rivets, unknown to the turn-of-the-century Ulster shipbuilders, could be a key to the calamity.

However, he and others stress that much remains unknown. “I’m not married to any particular theory,” he said, adding that he has examined only a few of the 3 million hull rivets.

As for the ultimate cause of the sinking, George Tulloch, president of RMS Titanic Inc., the company that owns salvage rights to the ship, cautioned: “I’m not sure it’s fair to take the iceberg off the block as the guilty party--or the people that hit it.”

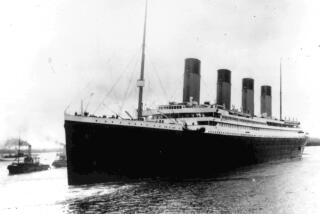

When it was completed on April 2, 1911, the RMS (Royal Mail Steamship) Titanic was the largest moving object made by man.

It was the size of an 11-story building, with a 101-ton rudder, and would carry 2,200 people--1,500 of them doomed--on its maiden voyage nine days later.

Although it was considered a model of safety, after it struck the iceberg, it filled rapidly with 34,000 tons of water and sank in less than three hours, coming to rest in three large pieces about 2 1/2 miles beneath the surface.

Since the discovery of the wreck, there have been eight expeditions and 140 descents to the site, yielding about 5,000 artifacts--among them hull plates and rivets that were turned over to scientists for analysis. Another expedition is set for this summer.

Much of the investigation has been done under the auspices of the 105-year-old Society of Naval Architects and Marine Engineers in Jersey City, N.J.--whose Marine Forensics Panel includes Foecke--and the Discovery Channel, which has funded some of the research.

Initial scrutiny turned up what appeared to be a weakness in the hull plates. Some of the inch-thick steel plates seemed to have properties that made them relatively brittle in cold water. Subsequent analysis, though, suggested that 2,000 steel plates used in the hull varied in quality.

During an expedition to the wreck in the summer of 1996, Paul K. Matthias, head of the Narragansett, R.I.-based Polaris Imaging Inc., used a special low-frequency sonar to scan the part of the hull damaged by the iceberg, now buried in 60 feet of bottom mud.

Contrary to long-held suspicions about a giant gash, Matthias found a series of six lateral openings in the starboard side that seemed to have been made by the Titanic bouncing off the iceberg as it scraped past.

“The position of these openings roughly corresponds to hull-plate boundaries,” Matthias said recently, throwing suspicion on the rivets. The experts studying the ship were intrigued.

“When I went back and analyzed Paul’s findings,” said William H. Garzke Jr., a naval architect with the New York ship design firm of Gibbs & Cox, who also heads the Naval Society’s forensic panel, “I said, ‘Hey, something’s up here. We need to look at one other element that we haven’t looked at very well, and that’s the rivets.’ ”

The duty fell to Foecke, an expert in fracture mechanics and a student of structural failures in World War II Liberty ships, who had been given several rivets for analysis a few months before.

Foecke was approached because of his expertise in the field. NIST, the former Bureau of Standards, has many materials experts at its huge Gaithersburg campus and a tradition of performing historical-type analyses.

In an interview, he said he sliced one of the hull rivets down the middle with a diamond-tipped saw, took it to his lab across the hall from his office and placed it under a special microscope called an optical metallograph.

The metallograph enabled Foecke to study the pattern of slag streaks running the length of the rivet and to measure the levels of slag.

Wrought iron must have some slag--usually about 2%--to give it strength, he said--”otherwise it would be taffy.” But too much makes it weak. The Titanic rivet, he found, had a dangerously high slag content of about 9%.

In addition, the streaks of slag, which should run lengthwise along the rivet, made a sudden 90-degree turn at one end, another serious flaw weakening the metal.

“This was really striking because the difference in mechanical behavior . . . I knew was huge,” he said. “To have the slag turned around this way, this is a major area of weakness.”

Within minutes, he was on the phone to Garzke.

“We suspected parted seams,” Foecke said. “We had sonar evidence. . . . [We] suspected rivets. So now we had a metallurgical reason.

“Eureka.”

But did that mean the Titanic was poorly built?

Said Garzke, the naval architect: “The shipyard bought the best material it could. . . . There was no reason for it to skimp on materials. Anybody who says they bought substandard stuff, that’s not true.”

Foecke said some people want to say that “bad steel sank the Titanic, bad rivets sank the Titanic.” But he pointed to the Titanic’s sister ship, Olympic, built at the same time and place with the same materials.

“It sailed for 27 years. It collided with two ships. It ran over and sank a submarine. It was hit by a dud torpedo. And it was called ‘Old Reliable’ and was scrapped in 1936. So it’s not what it’s made of, and what its design is.

“It’s also circumstance.”