Fixing broken supply chain will require major change in Long Beach, port chief says

- Share via

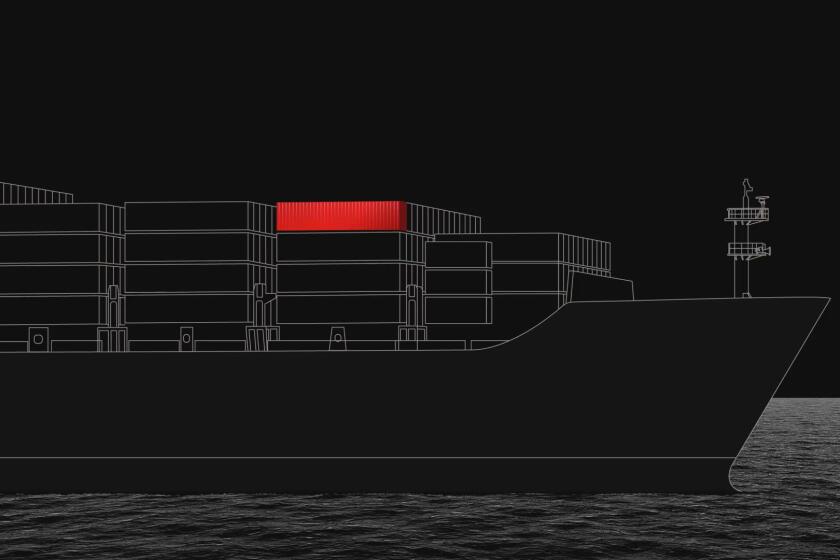

Southern California’s vital Port of Long Beach is still dealing with a backlog of waiting cargo vessels, its top official said Wednesday in renewing calls for transforming the supply chain into a round-the-clock operation.

In an annual state-of-the-port address, Executive Director Mario Cordero also outlined infrastructure and technology plans for improving movement of goods but said the issue goes beyond operations of the port.

About 40% of the container cargo entering the U.S. comes through the Port of Long Beach and the adjacent Port of Los Angeles, and both moved record volume last year. In October, President Biden announced a plan for round-the-clock operations, but it hasn’t happened.

“There are 168 hours in a week, and for the most part, our terminals are open less than half of those hours,” Cordero said in a video presentation. “Without expanding our terminals or building new facilities we could still handle more cargo by utilizing more of those hours. We’d also need truckers and warehouses to go 24/7.”

Follow a container of board games from China to St. Louis to see all the delays it encounters along the way.

Cordero said the Biden administration helped to establish the “framework” for 24/7 supply-chain operations.

“In Asia, on the other side of the Pacific Ocean, our trading partners are already operating 24/7. We need to make it our goal as well. It has to be our next great transformation,” Cordero said.

Looking ahead, Cordero said the Omicron variant of the coronavirus continues to bring uncertainty about the economy.

“Here at the Port of Long Beach we continue to work to clear backlogs of vessels offshore, which assures that we’ll remain moderately busy into the spring. Still, given our historic volumes in the first half of 2021, we’ll be hard pressed to see more than slow gains until perhaps the fall,” he said.

Among the initiatives, the port is working to maximize on-dock rail to accelerate cargo destined for Utah, Nevada, New Mexico and Arizona. That would free up equipment to support the Southern California market.

The port has also joined with a technology company to create a “supply-chain information highway,” a tool launching this month that will allow cargo to be tracked across various modes of transportation.

“All of this will help,” he said. “Still, we need to recognize that the supply chain isn’t so elastic that it can easily handle historic jumps in volume.”

Flexport CEO Ryan Petersen knows logistics. After touring the Port of L.A., he came up with some solutions to the container ship backlog.

More to Read

Inside the business of entertainment

The Wide Shot brings you news, analysis and insights on everything from streaming wars to production — and what it all means for the future.

You may occasionally receive promotional content from the Los Angeles Times.