Making space exploration more affordable

- Share via

Upstart aerospace companies such as SpaceX and Blue Origin are betting they can go head-to-head with the legacy launch providers on price by leveraging new technology and rocket manufacturing techniques. Here are some of them.

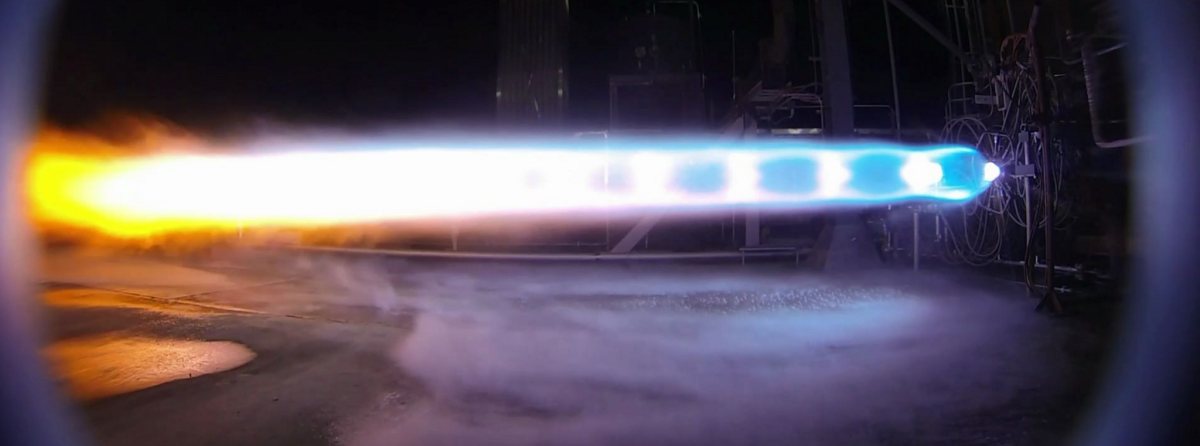

Methane

Most rocket engines that are powered by liquid fuel use either hydrogen and liquefied oxygen, or kerosene and liquid oxygen. Some companies see liquefied natural gas as an alternative.

Who’s using this: Blue Origin, SpaceX

Advantage: Widely available, cleaner, self-pressurizing

Additive manufacturing

Experts say additive manufacturing, known as 3-D printing, could be a game-changer in terms of cutting down the time and cost of producing rocket parts.

Who’s using this: United Launch Alliance, SpaceX, Blue Origin, Aerojet Rocketdyne

Advantages: Quicker production, cheaper to produce prototypes

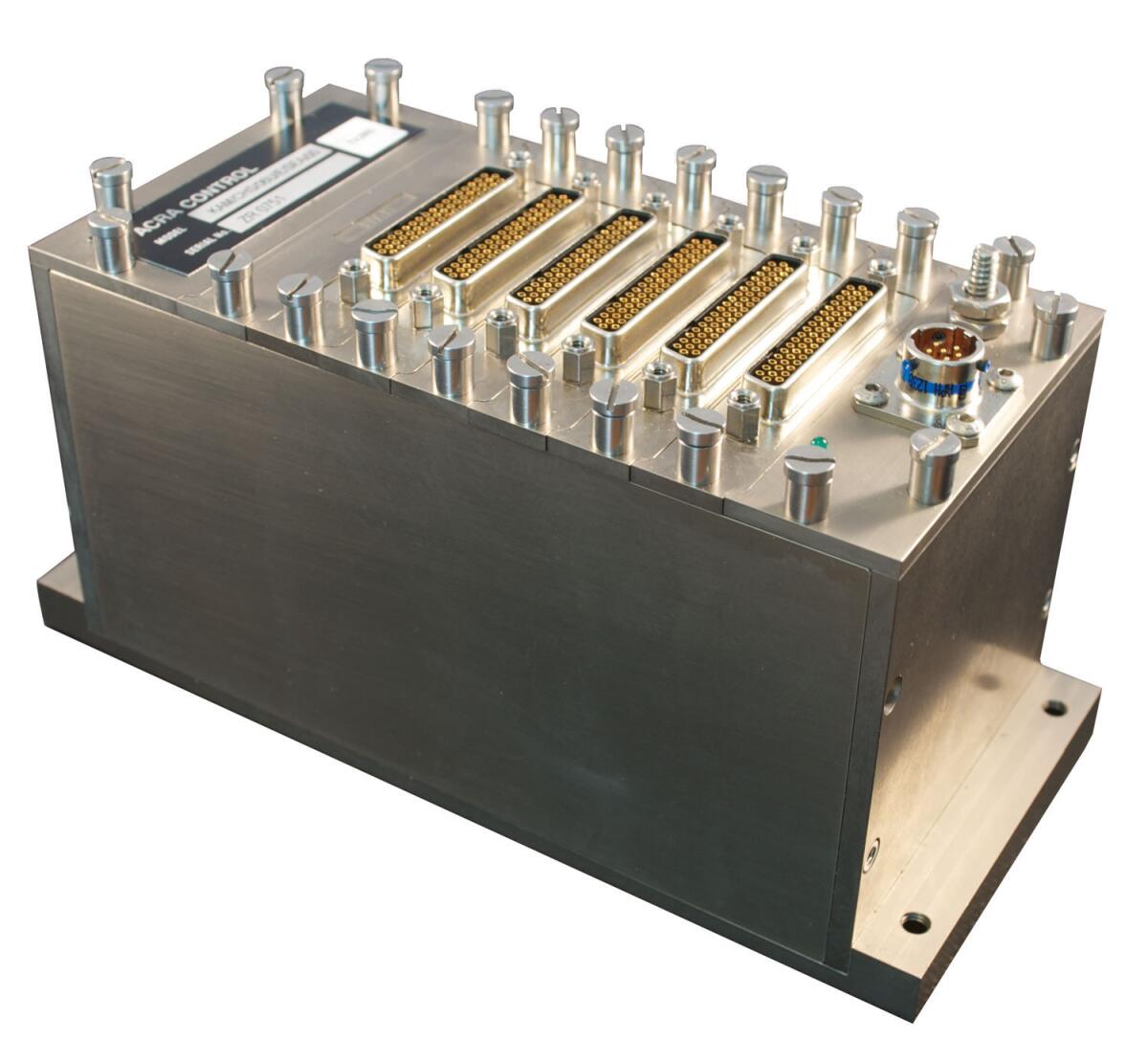

Commercial off-the-shelf parts

It’s not uncommon for aerospace companies to repurpose hardware that was developed for other industries. Now some companies are applying this idea to data systems.

Who’s using this: SpaceX, United Launch Alliance, Boeing, Virgin Galactic

Advantages: Cheaper production and development costs

Reusable rockets

Upstart aerospace companies have poured money and resources into developing a rocket that can be reused over and over again, much like commercial aircraft.

Who’s using it: SpaceX, Blue Origin

Advantage: Using a rocket engine at least 10, and maybe many more, times cuts launch costs

Sources: Blue Origin, SpaceX, Curtiss-Wright