Talk of Circuit Boards Keeps Things Humming at Nepcon

- Share via

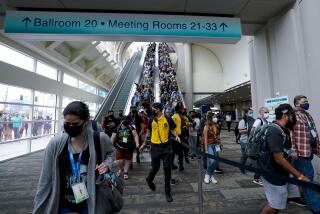

Nearly 1,000 makers of electronic production, testing and packaging equipment are showing off their latest wares today at Nepcon West 86, the final day of a three-day exhibition and conference devoted to anything and everything related to printed circuit boards and electronic assemblies.

The exhibitors have filled all three halls at the Anaheim Convention Center and spilled over into four temporary dome buildings outside. At least 77 companies from Orange County have displays at the exhibit and an additional 75 have come from Los Angeles County to join exhibitors from 35 other states and eight foreign countries.

Most of the attention at this year’s edition of Nepcon is focused on the emerging and highly automated “surface mounting” technology--the ability to put circuitry on both sides of a printed circuit board, the foundation for an electronic system.

Only about 10% of U.S. printed circuit makers employ this new technology, while about 30% of the Japanese industry has adopted the techniques, which require automated assembly and allow components to be made smaller and with greater reliability.

‘U.S. Definitely Behind’

“The United States is definitely behind Japan (in electronics) and may be behind the Europeans,” said Ron Pound, an electrical engineer and editor of Electronic Packaging & Production magazine. For many American electronic companies, Pound suggested, the scenario is similar to the situation that the U.S. car industry faced two decades ago--a reluctance to invest in new equipment, to learn new techniques and to take risks.

“The boom days (for electronics) are over,” said Jon Lucas, a manufacturer’s representative from Seattle. “Opportunities are going to have to be sought out and developed.”

Because of the automated nature of the new techniques, experts think that American electronics companies have the potential to become more competitive and recapture some of the assembly functions that have gone to countries with low labor costs, such as Malaysia, where some of the assembly is done by hand.

Electronic test equipment also is getting considerable attention at this year’s show. The new equipment allows components to be checked at multiple steps in the assembly process, a boon to an industry that has suffered from a high amount of waste because of the difficulty of testing during the manufacturing process.

Massive Demonstration

In a massive demonstration of some of the new techniques at the exhibit, 47 companies joined together to set up an operational, automated assembly line for printed circuit boards.

Customers and exhibitors alike consider the show a must, although only about 10% of the visitors actually agree to make purchases at such a show, officials said. The rest are “kicking tires,” one exhibitor said. They also are filling shopping bags with literature to take back to the home office.

“The show is awfully important,” said David Mayer, a spokesman for the Hartwell Corp. in Placentia, a maker of fasteners for circuit boards. “It generates a lot of leads.”

About 40,000 visitors are expected to pass through the convention halls by the time the show closes today, making it the largest Nepcon ever and the largest production electronics show in the nation.

One of those visitors was Jesse Peng, an engineer with Nan Ya Plastics Co. in Taiwan, who slowly searched the vast floor for electrical test and automatic processing machines for his company, which makes printed circuit boards. By noon Tuesday, Peng had found several machines that “might work” and had collected a stack of literature to take back to Taipei for company officials to peruse.

Closed a Deal

Exhibiting at Nepcon involves more than simply setting up a table with a demonstration or two and a stock of brochures. Mesa West Inc., an Anaheim-based maker of circuit board plating and processing systems, estimates that it will spend $10,000 on the show, including the $4,500 fee to rent its floor space, which is about the size of a small garage.

Paul Stubb, president of the Anaheim-based company, wasn’t complaining, however. Half an hour into the show, he closed the sale of one of his company’s processing systems, which carry price tags beginning at $90,000, “without any bells and whistles.” And Stubb said he doesn’t think that the electronics industry is in jeopardy in Orange and Los Angeles counties. His company’s technology, for example, “is on the leading edge,” he said. “Orange County has the momentum,” he said. “We will continue to be strong in electronics.”

Some companies try to attract attention at Nepcon the old-fashioned way--by having minimally attired women approach passers-by and offer brochures. These women, who typically are hired just for the duration of the convention, help lure customers who “might be reluctant to stop,” explained one executive, smiling broadly.

But such practices appear to be destined for the same fate as the manual assembly of circuit boards--extinction.

Because of the increasing number of women in electronics, such tactics are “going down hill fast,” said Jim Greif, a spokesman for the exhibit. “Women executives don’t relate well to it.”