FAA Orders Followed, Delta Says : Plane’s Record Shows No Data Tied to Crash Cause

- Share via

The Delta Air Lines Boeing 727 that crashed and burned Wednesday in Dallas experienced five mechanical problems in the past seven years serious enough to warrant reporting to the Federal Aviation Administration, but none seem to be related to the crash.

Early reports from both the FAA and the airline as well as from eyewitnesses and survivors of the crash indicated that a malfunction in at least one of the plane’s three engines--possibly the left one--might have been involved in the fatal accident at the Dallas-Ft. Worth Airport.

In Burlington, Mass., at the FAA’s New England Regional Office, Jay Pardee, chief of the agency’s engine certification branch, said the plane was powered by Pratt & Whitney JT8D engines. The FAA has issued five orders, called Airworthiness Directives, mandating inspections and possible repairs on such engines since 1985.

Previous Fatal Accident

One order, Pardee said, was related to another airline accident that caused fatalities, although he cautioned that it was too early to say whether circumstances in this instance were similar.

In that previous accident, a British Airtours Boeing 737, also powered by Pratt & Whitney JT8D engines, caught fire and exploded on Aug. 22, 1985, as it tried to take off from Manchester Airport in Great Britain. The aircraft was traveling at 110 m.p.h. on its takeoff roll when the accident happened.

The plane carried 137 persons. Fifty-four were killed.

England’s Accidents Investigation Branch found that the fire had started when the plane suffered an “uncontained engine explosion” on its port side. News reports said the engine explosion was caused when a combustor can--one of the chambers in which a jet engine burns fuel--broke loose. The combustor can severed a fuel line. Fuel ignited and caused a second explosion and general fire.

Less than a month later, on Sept. 6, 1985, a DC-9 powered by JT8D engines crashed after takeoff from Milwaukee’s Mitchell Airport, killing all 31 people aboard. A subsequent investigation by the National Transportation Safety Board found that an engine stall warning had gone off in the cockpit. Investigators also discovered engine parts on the runway.

As a result of these accidents, the FAA issued an Airworthiness Directive on Aug. 8, 1986, to all airlines operating planes with JT8D engines in the United States. The directive instructed the airlines to inspect these engines for cracks in their combustion chambers that might cause them to explode and break loose.

In Atlanta, Neil Monroe, a Delta spokesman, said the airline had complied with the FAA directive.

David Long, a Pratt & Whitney spokesman at the company’s headquarters in East Hartford, Conn., said the company had dispatched two investigators to the Dallas crash. He said the company routinely sends investigators to crashes involving aircraft powered by Pratt & Whitney engines. It was “way too early,” he said, to speculate on the cause of the crash.

Four Other Directives

The other four Airworthiness Directives issued on JT8D engines, Pardee said, called for:

--Inspection of fan blade attachment straps for cracks.

--Inspection of high pressure compressor spacers for cracks and their replacement within two years with more durable spacers.

--Inspection of outer combustion cases for cracks in the rear flange area.

--Inspection of grooves in low pressure turbine discs for wear and pitting.

The Delta 727 that crashed in Dallas was built by Boeing in 1973. Delta has been its only operator.

Because it was 15 years old at the time of its crash, the plane was still within what Boeing calls its economic service life. After 20 years, the manufacturer says, many aircraft begin to suffer an ever larger number of structural cracks.

Boeing spokesman David Jimenez said the plane had made 38,629 takeoffs and landings. Jack Gamble, another Boeing spokesman, said its 44,000 hours in the air were average for an aircraft of its age.

Two of the five mechanical problems requiring reports to the FAA over the past seven years have involved structural cracks. According to FAA records, one these Service Difficulty Reports cited a half-inch crack in the fuselage skin at the lower aft corner of the pilot’s side window, found in August of 1983.

A second cited a three-quarter inch crack in the fuselage skin at the upper aft corner of the captain’s windshield, also found in August of 1983.

Three Service Reports

The other three Service Difficulty Reports cited:

--A jammed aileron with flaps up at 15 degrees, discovered during a ground check in July of 1987.

--An “unsafe light” on its right main landing gear that would not go out, even after crew members had placed the gear handle in its “up” position.

--A scorched pillow case in an overhead rack.

Bobbie Mardis, a spokeswoman for the FAA, described these problems as very minor.

“From the records,” she said, “it looks like the plane was very well taken care of.”

More to Read

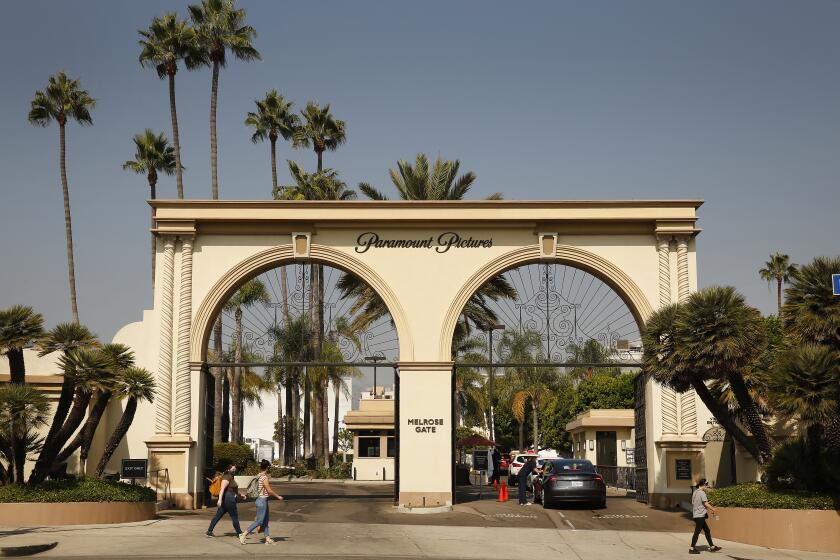

Inside the business of entertainment

The Wide Shot brings you news, analysis and insights on everything from streaming wars to production — and what it all means for the future.

You may occasionally receive promotional content from the Los Angeles Times.