The Great Trade War : Partnerships : U.S., Mexican Glassmakers’ Ties Break the Mold : Their alliance reflects a new way of doing business that has evolved as the countries’ economies become more integrated.

- Share via

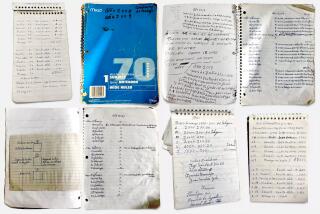

MONTERREY, Mexico — At age 23, Francisco Javier Morales is the envy of the Vitrocrisa glass factory. He is one of a half-dozen workers chosen to operate two fully automated tumbler decorating machines the plant just imported from Germany.

While other workers try painstakingly to visually match different color plates for glass decorating designs, Morales simply adjusts his eight-color, computerized machine and monitors the results. Because they are consistent, assuring quality at the rate of 50 glasses a minute, his productivity bonus is among the highest at the plant.

Vitrocrisa bought the machines to supply products that meet the quality standards of its new U.S. partner, Corning Inc. The designs on the glasses Morales decorates coordinate with Corning’s break-resistant Corelle dinnerware, currently sold throughout the United States and slated for introduction in Mexico later this year.

That puts Morales among the growing number of workers, consumers and retailers whose lives are changing because of a year-old alliance between two glass giants, New York state-based Corning and Vitrocrisa’s parent, Vitro, a $3-billion-a-year corporation with headquarters here.

The alliance is a forerunner of a new way of doing business that is becoming more prevalent as the U.S. and Mexican economies become more integrated.

The most obvious symbol of that unification, the North American Free Trade Agreement, faces strong opposition in the U.S. Congress over environmental and labor concerns. However, congressional opposition to NAFTA has done little to slow the pace of commerce across the border.

U.S.-Mexico trade has doubled over the last five years, and that’s not just because Americans are buying more tequila and Mexicans more Hershey bars.

The bulk of trade growth has been in engines and wood pulp, rather than finished products. And most of the commerce is within corporations, such as IBM, which sends U.S.-made microchips to Mexico and ships Mexican-made computer cords north. This intra-company commerce is the kind of complementary trade envisioned in NAFTA, and it is the base for the North American trade bloc.

Corporations that have not already integrated production among their own factories in the United States, Mexico and Canada are forming strategic alliances with partners in the other two countries.

Brewer Anheuser-Busch, retailer Kmart, Pepsi-Cola and denim-maker Cone Mills have all recently formed alliances with Mexican companies in deals similar to the Corning-Vitro partnership.

These partners insist that, unlike auto makers who have moved production to Mexico to take advantage of low wages while closing plants in the United States, their alliances will not cost jobs. Budweiser will not be made in Mexico any more than Modelo, Anheuser-Busch’s partner, plans to brew Corona beer in the United States, the companies insist.

The Corning-Vitro deal, company executives say, is a case of opposites attracting. The basis for the alliance is that they manufacture different--albeit, complementary--products. Moving production from one factory to another would not make sense, they say.

While Corning employees may not be hurt by this particular alliance, the trade agreement could cost the jobs of workers at other U.S. companies that compete directly with Vitro.

The high U.S. tariffs on household glassware, which Vitro has said make it difficult for it to sell in the United States, would drop quickly under NAFTA. Consumers would benefit from lower prices for imported glassware, but some U.S. manufacturers would be unable to compete.

A U.S. International Trade Commission report predicts that some segments of the industry could suffer production and employment losses of 6% to 15%. In the long term, however, other more competitive parts of the industry--manufacturers producing higher quality, lower cost goods--would increase production and employment by 16% or more, the study maintained.

That makes household glassware typical of the effects expected from NAFTA--some industries would lose production and jobs, while others gain.

By working together, Corning and Vitro are hoping to take advantage of increased trade as tariffs drop. Their alliance also shows how large, sophisticated corporations in both countries are likely to benefit from expanded trade at the expense of less efficient companies.

Last year, the companies set up twin joint ventures to make and merchandise their complementary product lines--cookware and dishes from Corning; glassware from Vitrocrisa. The Mexican company, called Vitro Corning and comprised mainly of Vitrocrisa, is 51% owned by Vitro and 49% Corning. Ownership proportions for the U.S. corporation with all of Corning’s consumer products business--called Corning Vitro--are reversed.

The link has already boosted cross-border trade in glassware and glass cookware by $14 million and set off an exchange of marketing and production techniques.

“Both sides have contributed something to make things better,” said Ernesto Martens, president of Vitro. “Corning factory outlets now have Vitro products, and we are importing Visions cookware,” a line of see-through glass pots and pans.

In fact, Vitro has taken over importing all Corning products into Mexico, to the delight of consumers like Rosa Maria Garza.

Garza, a Mexico City accountant, put her first piece of Corning Ware on a stove top 15 years ago, when her cousin from San Franciso brought her a piece of glassware as a gift. “I thought it was marvelous,” she recalls. “It was attractive and practical because it went right from the stove to the table and kept the food warm.”

But in Mexico, Corning products were hard to find and expensive. So, every year when Garza went to visit her cousin, she brought back another piece of Corning Ware. Now she can buy Corning products in Mexico. “I use more with my new microwave, and the prices have come down a lot,” she noted.

Corning prices have dropped 25% because of the Vitro-Corning partnership, said Victoria Alvarez, glassware buyer for Aurrera discount stores and Superama supermarkets.

“We tried to import Corning products on our own about four years ago, and it was a complete disaster,” she said. Lower tariffs should have made the imported goods cheaper, but there were other obstacles. Because of the small volume involved, wholesale prices were high. Add to that the money paid to middlemen and retail prices were prohibitively expensive.

With Vitro as the sole importer, broker fees are minimal. Also, prices are lower thanks to higher volume fostered in part by sophisticated marketing campaigns developed with help from Corning.

Those campaigns have meant big changes for the Corning employees who were sent to Monterrey to help develop them--as well as for consumers, who find an array of new products available.

When the companies introduced Visions see-through cookware, they sent representatives door to door with pamphlets promoting the new cookware. One of the houses where they stopped belonged to Armando Hernandez’s family.

Hernandez’s mother saved the pamphlet, hoping to buy the cookware set when she had money. Hernandez and his brothers and sisters took the hint. On Mother’s Day last year, they pooled their money and presented her with a complete set.

“The only problem is, she’s afraid to use it,” Hernandez, a student and part-time taxi driver, said, laughing.

Vitro-Corning sold over $10 million worth of Visions cookware to families like the Hernandezes in the first year.

“Eventually, we intend to have permanent Corning marketing people living in Monterrey, looking out for Corning products,” said John Loose, chairman of Corning-Vitro Corp., the U.S. joint venture.

Finding volunteers will not be a problem, added the firm’s vice president for worldwide marketing, Hayward Gipson. “We have a small but effective group of people, standing in line, waving their hands to go to Monterrey,” he said.

In addition to the opportunity to sell Corning goods more effectively in Mexico, the alliance with Vitro has brought new products to U.S. consumers.

“The one category we have never been able to successfully crack is glassware,” said Loose. At the same time, Vitrocrisa was having trouble making a dent in the U.S. market.

By making Vitrocrisa products part of the recognized Corning Designs product line, the partners increased sales in the United States to $5 million in 1992 from $1 million a year earlier.

Based on the success of their joint marketing efforts, the companies have begun joint production.

Making Corelle glasses in Mexico solves a sticky problem for Corning. Consumers wanted glasses to match their dinnerware, but Corning had no way to make them.

The company tried licensing the designs, but was not satisfied with the quality. When it withdrew the license, other companies copied the designs without permission, but with similarly poor quality.

Corning turned to its new partner to solve the problem.

Vitro knew exactly where to go for machines that would decorate glasses up to Corning standards: Bunde, Germany, the headquarters of Kamman.

Besides turning out high-quality glasses in quantity, the machines improved working conditions for the six operators selected to run them.

“Everybody would like this kind of a machine,” said Jorge Garza, who heads Vitrocrisa’s decorating department, as Morales refilled the paint trays on the newest decorator. But only three operators--one per shift--were selected for each.

Morales, who has worked at Vitrocrisa for six years, was the youngest worker picked for retraining. Others were more like 41-year-old Jorge Antonio Gonzales Rodriguez, a 21-year Vitrocrisa veteran pleased, finally, to be on a job where he doesn’t “get paint all over my fingers.”

Their pleasure, however, conceals a downside to the trade-related economic change overtaking Mexico: As Mexican companies use more sophisticated machines to make world-quality products, fewer jobs will be available for unskilled workers.

The main environmental effect of Vitro’s production for Corning is to reduce the lead content of the paints being used on glasses, in order to meet U.S. standards. The machines paint onto the glass with brushes and do not create emissions.

Sixteen patterns of Corelle glasses take up about two-thirds of the machines’ capacity, leaving time to produce designs for the domestic market. Taking a cue from Corning, Vitrocrisa has begun ordering glasses to match its dinnerware patterns. The company also uses the lower-lead paint on glasses for the Mexican market.

“We have made a lot of adjustments in working with Corning,” said Garza. “I feel an enormous satisfaction in knowing that we are decorating items up to international standards.”

More to Read

Inside the business of entertainment

The Wide Shot brings you news, analysis and insights on everything from streaming wars to production — and what it all means for the future.

You may occasionally receive promotional content from the Los Angeles Times.