CSUN and MiniMed Seek Synergy on Campus

- Share via

Educators at Cal State Northridge are growing eager for a close-up look at their new biotechnical neighbor as workers building MiniMed Inc.’s $70-million headquarters recently passed the three-quarters mark at CSUN’s North Campus tract.

But that’s not all. The school’s neighbors are so happy to see MiniMed move in that they’ve elected company Chairman and Chief Executive Alfred E. Mann as honorary mayor of Northridge. And economic development strategists believe the headquarters’ opening, set for Aug. 11, will herald a future “golden triangle” of advanced health sciences industries straddling the West Valley-Thousand Oaks region.

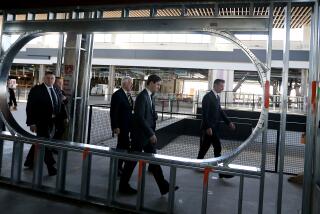

Mann is excited too. He recently showed off the building, pausing at one point in the lobby, where a soaring two-story curved-glass facade will provide many visitors with their first impression of the fast-growing company.

“We want people to think of MiniMed as a secure and forward-looking company,” said the 74-year-old executive, stepping agilely around lumber scraps and stacked pipes. “Which we are.”

MiniMed has built an impressive financial record by improving diabetes treatment for millions of patients, with easy-to-use, miniaturized insulin delivery.

The company has boosted its earnings and revenue each year since going public in 1995. For the first quarter ended March 31, it reported net income of $6.2 million on sales of $60.3 million, up from $3.8 million on $40.9 million in sales for the like quarter in 1999.

The company stock, trading at under $60 a year ago, closed Monday at $112, down $4.44.

Merrill Lynch analyst Susan Vissers Lisa recently rated the company a long-term buy, based on current market penetration of under 10%, anticipated growth of the patient population and new products in the pipeline. She projects sales this year to reach $300 million--a 41% increase over 1999--and to climb to $765 million by 2003.

*

MiniMed’s move to the larger quarters from a smaller office-lab complex in Sylmar will give the company room to grow. But just as important, the synergy it develops with the academic leaders and students has the potential to make CSUN a key biotechnology center, most observers agree.

CSUN and MiniMed began courting each other in 1997 after campus administrators--seeking long-term rental income on their vacant land but facing local opposition--scrapped a planned big-box retail center.

The 65-acre North Campus parcel south of Devonshire Street between Lindley and Zelzah avenues was long known as Devonshire Downs, when for decades it hosted festive throngs at horse races, fairs and rock concerts.

The company and school agreed on a 19-acre lease in January 1998 and Mann later obtained options giving him a hold on a total of 40 acres. The university has so far failed in a bid to woo an entertainment industry tenant to its 20 remaining acres, but the land that until recently was home to weed-choked parking lots, a used-car dealer and a few rickety wooden structures now bustles with truck traffic and hundreds of construction workers.

“This is a partnership with business and the university that’s going to do nothing but enhance the area,” said Richard A. Hardman, chief executive of the Northridge/Porter Ranch Chamber of Commerce, the group that gave Mann the ceremonial mayoral title. “It’s a win-win for everybody.” Mann said MiniMed now has 1,400 employees working in the company’s 150,000-square-foot office-lab complex at 12744 San Fernando Road. They’ll leave behind room for growth of two other Mann companies, Mann Research Group and Advanced Bionics Inc. Their new 508,000-square-foot complex--about one-third the floor space of the Northridge Fashion Center--is taking form as an example of modern office-research-manufacturing design.

The 20,000-cubic-yard foundation on deeply recompacted soil is designed to help it withstand a magnitude 8.5 earthquake. It has state-of-the-art backup generating, air pollution and hazardous waste management systems. Its acres of clean rooms with precise temperature and humidity controls and particulate filtration are designed for medical-device assembly on a massive scale.

Arrayed in three sprawling two-story wings around a central atrium--no separate buildings means products are never taken outside--the building will house more than 4,500 manufacturing, research-development and administrative workers, including third-party pay facilitators and hundreds of educators and counselors who will advise both patients and health professionals.

Educating consumer and health providers in new technology--in this case insulin-delivery methods that replace self-injection therapy that had held sway for generations--has been a key component of MiniMed’s success, Mann said.

*

The building also contains a 185-seat theater-style multimedia conference center aptly embodying the nascent synergy between company and university. It’s designed not only for sales and training seminars but also college classes where educators will be drawing on MiniMed’s expertise as a learning resource.

“What’s most interesting to me is their sensor technology and its integration with drug delivery--that’s where it’s at,” said Edward J. Carroll Jr., CSUN dean of science and mathematics.

But still, school and enterprise have a lot of work ahead of them in building strong working relationships, said Larry Caretto, CSUN’s dean of engineering and computer science.

For one thing, the two sides need to talk out MiniMed executives’ interest in career-enhancing enrichment and graduate-level courses, Caretto said. He added that it’s likely the school will design curricula for sales and administrative employees seeking to learn more about the technical side of the company’s operation and, conversely, for technical workers who want to learn more about the finance and business side.

But the key focus now is on developing internships and exploring how to tailor graduate programs based on MiniMed’s research and development activities, Caretto said.

“We’re still in a get-acquainted phase,” Caretto said. “We’re getting it in front of the faculty and department chairs to meet the appropriate people at MiniMed to build these appropriate kinds of links.”

The need for MiniMed to quickly acquire a highly trained work force--that could include internship programs for students--is illustrated by Mann’s production plans for glucose sensors, one of the company’s key growth products.

*

MiniMed’s continuous glucose sensor, a short-term implanted device currently marketed for clinical use, is designed to do just what its name implies, that is provide a constant reading of blood glucose levels that require administration of insulin.

Mann said his Sylmar workers produce 10,000 glucose sensors a month. He recently took delivery of machinery prototypes capable of producing 100,000 sensors a month. Meanwhile, the company is preparing an FDA premarket approval application for commercial versions of the sensor, designed for marketing directly to the consumer.

Once the production machinery is designed and approval granted, MiniMed would increase sensor production to 3 million a month.

MiniMed also is on the verge of a medical breakthrough, with its first animal trials underway of implantable glucose-monitoring and insulin-delivery systems. That’s a key step toward human trials next year of a true artificial pancreas, Mann’s long-held vision for controlling the often-deadly disease.

MiniMed is developing systems to treat AIDS, cancer and pulmonary hypertension, with a long-term goal of building manufacturing operations in Europe to serve the global population.

But even as production moves overseas, the Southland will remain a major biotechnology center, said Ahmed Enany, executive director of the Southern California Biomedical Council, the group that brought CSUN and MiniMed together as part of a strategy to broker underutilized college campuses to high-technology entrepreneurs.

But for now, it’s time for soul-searching at both MiniMed and CSUN before that synergy can grow, Enany said.

“It’s a learning process for both sides. This hasn’t been done before and there’s no model around that you emulate,” he said. “Every college has its own specific needs and problems. The two parties are not going to be happy all the time, but you have to work it out to accomplish the objectives of both sides.”

More to Read

Inside the business of entertainment

The Wide Shot brings you news, analysis and insights on everything from streaming wars to production — and what it all means for the future.

You may occasionally receive promotional content from the Los Angeles Times.