Unequal Treatment: Where employers use quality control to shape healthcare

- Share via

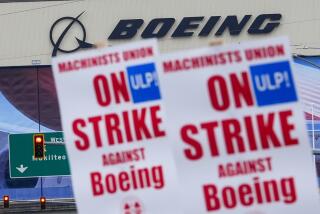

Reporting from EVERETT, Wash. — Forty miles north of Seattle, in the largest building in the world, Boeing assembles its biggest commercial airliners.

Thousands of workers on a 98-acre factory floor piece together hulking wings and fuselage pieces, miles of electrical wiring and millions of rivets on a production line so precisely choreographed that Boeing can roll out a new jet every other day. The largest plane built here, the 747, has some 6 million parts.

With similar attention to detail, Boeing has helped shape medical care in and around Seattle, one of the healthiest regions of the country.

Employer-provided coverage is the backbone of the U.S. health system, with more than half of Americans getting insurance through work. Most businesses, however, are reluctant to manage medical providers as they might other key suppliers.

It’s different on Puget Sound. Boeing and other major employers here, including Starbucks and Costco, have aggressively pushed local hospitals and doctors to meet the kinds of rigorous standards they use to build airplanes or brew coffee.

That has nurtured an unusual relationship between employers and medical centers that has affected the way patients are treated for back pain, how they are counseled for depression, even how they schedule doctors’ appointments.

The results include better health, higher patient satisfaction and in some cases lower costs, making the community a model as employers and governments nationwide look for ways to improve care.

“In most communities, medical providers and employers don’t even talk,” said Dr. Gary Kaplan, chief executive of Seattle’s Virginia Mason Medical Center, one of the nation’s top hospitals. “Here, that conversation has made a profound difference in everything we do.”

Inspired in part by Boeing, Virginia Mason is among several local medical centers that use the same quality assurance system the aircraft company relies on at its plants, including standardized processes and precise scheduling to boost efficiency.

That translates into a different kind of medical care for such patients as Bob Mannschreck, a 51-year-old manager for a logistics company. He has suffered from back pain since a skiing accident in his 20s.

When the pain worsened, radiating down his right leg and making standing difficult, Mannschreck called Virginia Mason’s Spine Clinic in downtown Seattle.

He got an appointment right away. When he arrived for his 9:50 a.m. slot, his 70-minute session moved like a production line.

There was no wait. In the exam room, a medical assistant began to put information about Mannschreck’s pain, medications and medical history into an electronic record within minutes.

At 10 a.m., a physical therapist arrived and began gently probing Mannschreck’s back for pain, testing his reflexes and running him through exercises to check his mobility.

At 10:21 a.m., Dr. Alison Putnam, a rehab physician, joined them in an unusual team system developed by the clinic.

Putnam asked the therapist to describe Mannschreck’s symptoms, a communication technique that shows patients their concerns are understood. She then conducted a short exam of her own.

Putnam told Mannschreck the pain could be from a herniated disk or an irritated joint in his lower back or pelvis. She suggested an anti-inflammatory drug and four to six weeks of physical therapy.

If the pain remained or worsened, she said, he should call immediately and they would discuss more aggressive steps, including an MRI or an injection.

Putnam finished by 10:40. In the remainder of the appointment, the therapist worked with Mannschreck on abdominal exercises to relieve pressure on his hips and lower back before scheduling his next therapy appointment.

Mannschreck was done by 11 a.m.

His rigidly scheduled exam was no accident. For more than a decade, Virginia Mason, a nearly century-old community medical system, has worked to adapt a production system pioneered by Toyota and used by Boeing to cut waste and standardize high-quality outcomes.

Implementing the system took on new urgency when a group of Seattle-area employers working with insurer Aetna threatened to stop using the medical center because it was too expensive.

Instead of fighting the employers, Virginia Mason began working with them to redesign the care they were concerned about most: treatments for back pain, sinusitis and other common conditions that kept employees out of work.

“When we started looking at where our costs were too high and where our inefficiencies were, we found them everywhere,” said Kaplan, the chief executive.

Patients with back pain frequently waited a month or more to get an appointment. They were given unnecessary tests or referred to specialists when they actually needed physical therapy. The consequences for patients were higher bills, spotty access and uneven results.

Starbucks, which worked with Virginia Mason on spine care, demanded a straightforward bottom line: same-day access for employees, no unnecessary medical care and 100% customer satisfaction.

“They said this was a supply chain issue,” recalled Dr. Robert Mecklenburg, who led Virginia Mason’s redesign initiative. “They expected certain standards from their suppliers. We were no different.”

Some of the changes Virginia Mason made were simple. The spine clinic began reserving slots in the schedule for same-day appointments for patients with acute pain.

Doctors at the clinic created a new form for ordering MRIs that requires doctors to attest that patients meet one of eight criteria. Unnecessary imaging drives up costs and exposes patients to potentially harmful radiation, studies suggest.

Most revolutionary is the clinic’s carefully structured system for seeing patients like Mannschreck, which is designed to maximize use of physicians’ time and better respond to what patients want: quick care that gets them well quickly.

A patient spends most of an exam with a therapist, who can do basic diagnostic testing and is often better at communicating with patients than a doctor, clinic leaders concluded.

The doctor comes into the exam after 30 minutes, gets a briefing, then develops a care plan with the patient and therapist and can usually leave after 20 minutes.

Better use of doctors allowed Virginia Mason to eliminate backlogs nearly overnight.

Fewer unnecessary tests and more use of therapists — which the medical center calculated cost about $1 a minute, compared with $4 a minute for a doctor — led to lower costs.

The more standardized, efficient system also meant better outcomes.

Virginia Mason patients with back ailments typically need four to five visits to recover, compared with 10 nationally. The clinic’s patients also return to work more quickly, missing two days on average compared with five elsewhere, survey data show.

That’s key for employers. “Our ability to keep people healthy and get them back to work quickly is critical,” said Jeff White, director of Boeing’s health benefits strategy.

Patients also appreciate the efficiency. “When you are immobile and in pain, time is of the essence,” said Marcy Naismith, a 36-year-old interior designer who got in right away after injuring her back lifting one of her 2-year-old twins.

In recent years, Virginia Mason worked with other employers, including Costco, Nordstrom and the city of Seattle, to redesign care systems for headaches, joint pain and noncancerous breast lumps.

Similar relationships between employers and medical systems are transforming care elsewhere in the region.

Prompted by the state of Washington, which provides coverage to some 350,000 public employees and retirees, Group Health Cooperative, another leading Seattle-area system, implemented a groundbreaking method for improving communication between doctors and patients who may need surgery.

North of Seattle, Boeing helped the Everett Clinic build what is considered a national model of team-based care for very sick patients.

Now, the aviation giant is working with the state’s largest health systems — UW Medicine, Providence Health & Services and Swedish Health Services — on a new project to deliver higher-quality, lower-cost care for about 30,000 Boeing employees and retirees.

“When Boeing says, ‘We need better care,’ you listen,” said Dr. Joseph Gifford, who heads an alliance of the Providence and Swedish systems that works with the company.

Today, businesses in a handful of states, including Minnesota, Maine, New York and Arkansas, are similarly pushing healthcare systems to improve.

It remains unclear whether that kind of business leadership will develop elsewhere. Few companies have as much local clout as Boeing, which employs about 80,000 people in Washington state. And few communities have as many health systems that are willing to work with local employers as Seattle.

“You need people who are willing to sit down in a room together and work on community problems,” said Helen Darling, former longtime head of the National Business Group on Health, an association of large employers. “That is very hard to replicate.”

But as businesses increasingly move workers to high-deductible health plans that force them to pay more out of pocket, employers may get more engaged with local health systems to help employees shop for care, predicted Leah Binder, president of the Leapfrog Group, a national nonprofit formed by employers to track hospital quality.

“Employers,” she said, “may not have a choice.”

More to Read

Inside the business of entertainment

The Wide Shot brings you news, analysis and insights on everything from streaming wars to production — and what it all means for the future.

You may occasionally receive promotional content from the Los Angeles Times.