New Plant Will Use Scraps to Help Power Carpet Factory

- Share via

DALTON, Ga. — Here in the “Carpet Capital of the World,” the large manufacturing plants that supply almost half the nation’s carpet also pump out reams of wasted scraps that eventually wind up in landfills.

Next month, the world’s largest carpet maker will do something about the problem when it begins operating a one-of-a-kind power plant that will be fueled by the 16,000 tons of overruns, rejects and remnants it turns out every year.

Shaw Industries Inc. hopes that the $10-million plant, which will power one of its main factories, can help the company save the $2.5 million a year that would have gone to buy fuel oil.

If the project proves successful, its designers expect it to reverberate throughout the industry and particularly this northwest Georgia town, where the rolling hills are dotted with carpet factories, warehouses and discount outlets.

“Everybody is watching, and we’ve been looking for years to find a way to convert waste carpet that makes sense,” said Howard Elder, research director for competitor J & J Industries. But Elder quickly added that others would follow Shaw’s lead only if it proved to be economically viable.

The plant’s engineers say the process is environmentally sound, emitting roughly the same amount of pollution as natural gas. In addition to carpet scraps, the plant also will burn the 6,000 tons of sawdust the company produces every year during the manufacturing of wood flooring.

The Carpet and Rug Institute says 4.7 billion pounds of carpet is dumped in U.S. landfills each year.

To the man who helped persuade his company to embrace the idea, it all makes sense -- especially in light of rising oil costs.

“Why pay someone to dig it out of the ground and pay someone else to put it in the landfill?” asked Gary Nichols, Shaw’s corporate energy manager, noting that most carpet is made from plastics and other oil products.

Sure, changing waste carpet into energy may seem like a shoo-in for the carpet industry.

A pound of carpeting has roughly the same energy potential as a pound of coal, Nichols said. But years of failed attempts and bad news have long discouraged industry leaders from taking the next step.

Because carpet is made from plastic materials, it often melted, ruining some previous attempts to have it converted to power. Other endeavors failed when the process proved too toxic to meet air pollution standards. And an explosion at a carpet-incinerating boiler in nearby Cartersville years ago didn’t help matters.

Yet as energy costs rose, the premise that waste carpeting could be used to fuel production suddenly became more viable, and Nichols pleaded for years with the company’s hierarchy to take another look at converting waste carpet into energy.

The result: Shaw Industries joined with engineers from Siemens Building Technology to design a plant they think perfects the once-faulty conversion process.

The shiny high-tech plant stands in stark contrast to the nearby factory -- a sprawling gray building where parachutes were made during World War II -- it will help power.

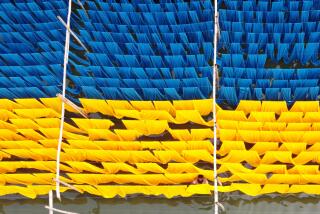

When the power plant goes on line this summer, truckloads of carpet will be stacked three stories high in a cavernous warehouse, waiting to be sent through an imposing shredder. Those remnants will then go to the gasifier, which resembles an oven and converts the scraps into a synthetic gas. The gas will be pushed through two pollution-controlling processes before being funneled to the factory, where it can be burned much like natural gas to help create 2 million yards of new carpet each year.

Shaw, a privately held subsidiary of billionaire investor Warren Buffett’s Berkshire Hathaway Inc., has 30,000 employees and recorded annual sales of $4.66 billion in 2003, the most recent revenue data available.

“This process has very far-reaching ramifications,” said Clark Wiedetz, a Siemens business development manager. “It’s the first of its kind, and the interest even during the last 15 months has been incredible.”

Most of that interest has come from Shaw’s competitors, who regularly ask about the project, Nichols said. “Right now, everybody’s skeptical.”

To the carpet industry, the new plant is a “win-win situation,” said Bob Peoples, executive director of the environmental group Carpet America Recovery Effort and an environmental sustainability expert. “This is a major step forward. This is one potential solution to the landfill problem we face.”

If successful, the technology’s biggest proponents look to be landfill operators. “Everybody supports it,” said Harvey Levitt, operations manager for the city of Dalton’s solid waste authority. “I just hope it works.”

More to Read

Inside the business of entertainment

The Wide Shot brings you news, analysis and insights on everything from streaming wars to production — and what it all means for the future.

You may occasionally receive promotional content from the Los Angeles Times.