Fresh Meat, Spices and Hard Work Go Into Southern Comfort Food : Sausage: Makers of homemade country links say the skinny, store-bought kind don’t compare.

- Share via

Sausage actually sounds good, spitting and sizzling in a cast-iron skillet. But it’s that roaming rich and savory aroma that yanks you out from under the covers on the coldest of mornings.

For Southerners, the scent of country sausage frying on the stove signals the arrival of cool weather, like fresh wood smoke and dead leaves. Years ago--before we knew arteries clog so easily--farmers slaughtered hogs during November and December and ground and stuffed tubs of sagey sausage. It still tastes best this time of year. With scrambled eggs, fat biscuits and buttered grits, sausage may be the ultimate Southern comfort food, warmer than the heaviest quilt.

The real, old-fashioned kind is hard to find these days, although the supermarket coolers are stacked with skinny links, peddled by country and Western singers and giant pork conglomerates. Most folks, it seems, don’t want to take the trouble to make it the way it should be.

“It’s part of the changing of the times, I guess,” says Carolyn Vann who creates her own country sausage--mild and hot, bulk and link--every week at the B&C; Meat Mart in Suffolk, Va. Vann learned to make it growing up near Edenton, N.C., more than 25 years ago. “Some people don’t realize the difference,” she says. “You just can’t compare homemade sausage to the store-bought kind.”

Besides Vann, there are a few other sausage makers scattered throughout the South--in the little grocery stores and old butcher shops--who still know how to season, grind and stuff the meat. The right way. They’ve inherited recipes from their parents and learned to twist and tie the links by watching expert farm women in the kitchen.

But these breakfast-food artisans say the secret is not in the right spice blend or the correct link technique. It’s simple: Making good country sausage requires fresh meat and hard work.

The sausage can’t get any fresher than at Young’s Meat Barn in the little town of Parksley on Virginia’s Eastern Shore. Between three and 10 o’clock every Monday morning, Ralph Young and his son Franklin slaughter 30 to 45 hogs in the back of their little red building off Route 13.

A couple of days later, that same fresh pork is stuffed into sausage casings and curled up in the meat case out front.

The fact that the meat goes directly from hoof to link all under one roof may be the biggest reason Young’s sausage is so famous--why the guy from Washington State flies 10 pounds home in his suitcase every few weeks, and why the Youngs sometimes sell three tons a week.

“Yeah, that could be it,” grunts 61-year-old Ralph. “Ours is sure fresh,” adds Franklin.

Ralph learned meat cutting as a boy, and has been in the business for 24 years. The Youngs put out all kinds of pork parts for their ravenous customers--pigs’ feet, ears and livers--but the sausage is still the big seller. On one morning, they had moved 400 pounds of the pink, plump links and bulk meat in four hours and the crew was cranking out more in the back, trying to keep up with demand. The hungry patrons eye it through the glass window and then buy five pounds or more at a time at $2.29 a pound.

“Goodness, we’ve sold a lot of sausage these past couple of days,” declares salesclerk Alma Chew, over the whine of a band saw.

The Youngs drop nothing but the best hams, butts and shoulders into their fancy grinder, which chews up the pork in 100-pound batches. They stick to a 70-30 lean-to-fat formula, and they say that’s the key to sausage making.

“If it’s too lean, it’ll cook too hard,” says Ralph, “and if it’s too fat, it’s just no good.”

Their ratios may vary slightly, but the other sausage makers all agree that a good mixture of fat and lean is necessary to keep it tasty and juicy.

“It’s got to be lean enough not to stick, but fat enough so you don’t need to put any grease in the pan,” says Curtis Ansell, who makes and sells sausage at his little supermarket in the Back Bay area of Norfolk. Ansell says his 70-year-old-sister, Edna Spence, can eyeball the meat and tell how much fat to add before grinding it.

Bill Newbern of Portsmouth makes his with 60% lean meat, all from neck portions. “Fat makes the difference,” he says. “Got to have the mixture.”

Newbern, who resembles a jumbo link himself, cuts and sells fresh pork chops, roasts and ribs at Newbern’s Family Meats in Norfolk. But it’s his mild and hot country sausage that really draws folks to the wooden lean-to building.

“People who buy sausage from me used to go to Carolina every week to get it,” he claims.

A Portsmouth native, the 47-year-old Newbern says he learned to use a knife and bone saw when he was 12, working part time in stores after school. But he picked up his famous sausage recipe 21 years ago from an old hog farmer down near Goldsboro, N.C., while he was cutting meat at the Piggly Wiggly. And it took some real talking to get the recipe out of the old guy, Newbern says. There’s black pepper, cayenne, sage, paprika and salt in his Carolina sausage, he says, but no MSG and no fancy preservatives.

This is the motto of all the country sausage makers: Nothing but the purest, natural ingredients go into the meat.

But the rest of the mixture is pretty simple. The Youngs say they use only sage, salt and pepper. And Joe Suraci, owner of Joe’s Old Fashioned Meat Market in Virginia Beach, says he created his recipe by just eating it and reading the label on the store-bought brands.

Suraci, who grew up in New York State, first made chorizo and Italian sausage, but now his country version is also a big seller. Despite his Yankee accent, his sausage tastes like the real Southern thing.

There are tricks to the trade, though. For instance, Bill Newbern and Curtis Ansell both rub the spices into the meat and marinate it for 24 hours before grinding it.

Like Newbern, Ansell says he learned the secrets from a farmer 15 years ago who had decided to get out of the business because he was getting too old to turn the grinder.

Ansell’s sister Edna has been making sausage since she was 10, and she still takes on most of the grinding and stuffing responsibilities at the little supermarket in Virginia Beach.

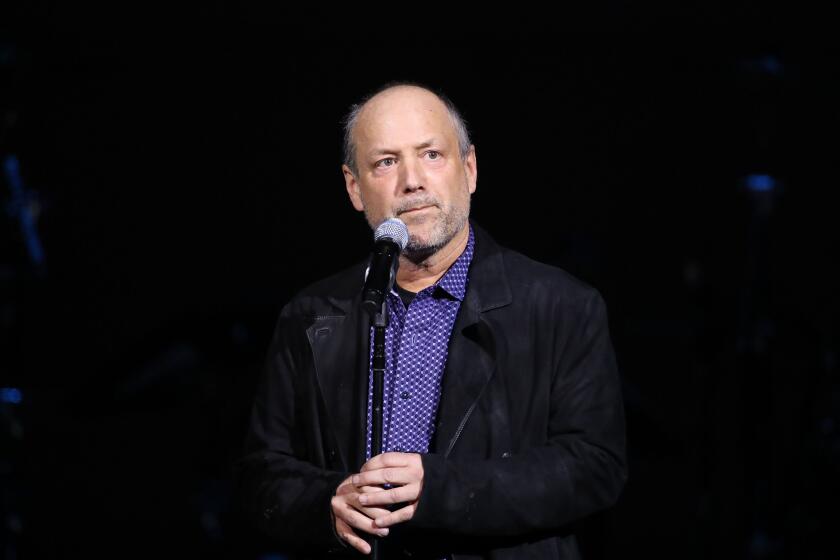

Edna cuts up about 280 pounds of fresh pork butts every Monday and marinates the meat on Tuesday. Early the next morning, at a table in the back under a picture of Curtis posing with East Coast chicken king Frank Perdue, Edna and three helpers run the pork through the grinder until it looks like hamburger. They attach the deflated and cleaned hog intestine casing to a nozzle on the sausage stuffer and push a lever that mashes the meat out into the casing. Edna then twists and ties the four-foot sausage “snake” into links. Six of her links make a pound--and you don’t have to set them on the scale to know that. “I just enjoy doing it,” Edna says.

For a long time, the Ansells used an old creaky stuffer borrowed from the farmer who gave them the recipe. Then, a couple of years ago, they ordered a shiny steel machine from Buffalo, N.Y.

“Wasn’t worth a durn,” says Ansell. “The meat was squirtin’ up over the edges.” A local woman then loaned them a black iron antique stuffer--about twice as tall as a big food processor--and that’s what Edna uses every week now.

Ansell’s sausage gets around. The hunters who come to Back Bay from West Virginia every year take it home with them. And visitors from Philadelphia and Baltimore also load up their car trunks before heading back to the big city. Of course, there are regular sausage customers from “uptown.”

Daring folks especially crave Ansell’s hot country sausage, which can explode in your mouth like little firecrackers, depending on how much crushed red pepper Edna sprinkles in.

“People will come back sometimes and swear that we made it too hot,” Ansell says, laughing. So once in a while, Edna will fry up a sample, right there in the store, to make sure she’s got the seasoning right. It smells great, and on those days the customers almost climb over the meat case to get a bundle.

“I’m proud of our sausage,” Ansell says, “because we have it and everybody else doesn’t.”

All of the sausage makers take pride in their dying skills, but they aren’t exactly living testimonials for their product.

Most of them don’t eat sausage.

“Nope, I’m allergic to pork,” Ansell says. “I swell up and start to itch.” Edna says she can’t eat it because of a cholesterol problem.

“I’ve slacked off because of my health,” Ralph Young says. “I just don’t care too much for pork,” adds his son Franklin.

Elizabeth Vann loves sausage, but her doctor will allow nary a link because of her “high blood.”

Then there’s 6-foot-1, 280-pound Bill Newbern. You’d probably have to wrestle him to scrape it off his breakfast plate.

“I love it scrambled in eggs and topped with country cheese,” he says with a big grin.

More to Read

Eat your way across L.A.

Get our weekly Tasting Notes newsletter for reviews, news and more.

You may occasionally receive promotional content from the Los Angeles Times.