He Kneads What France Wants

- Share via

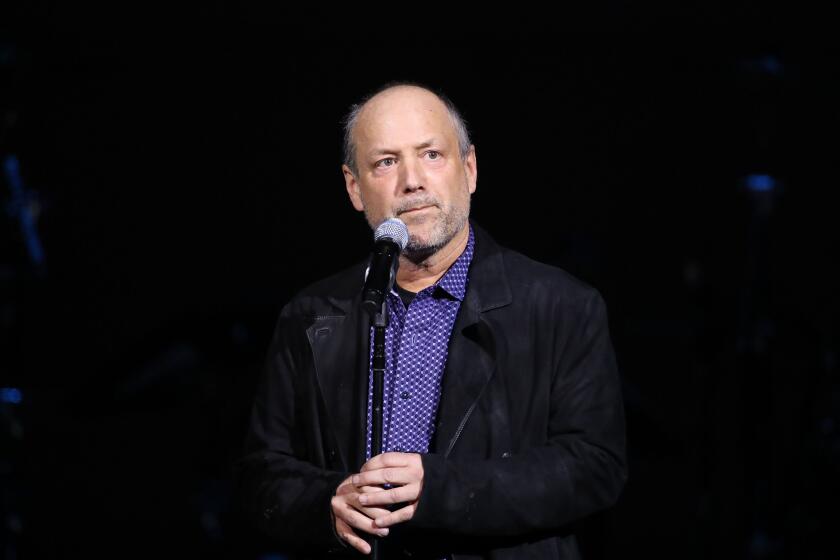

CHATEAU DE FEY, Burgundy, France — Robert Haumonte has been a baker since he was 14. To look at his ruddy face and muscled shoulders, you’d think he was a farmer, until you catch sight of the hands--flat-fingered and square, with the pale sheen

Artisan bakers such as Haumonte are vital to the French habit of consuming baguettes at breakfast, lunch and dinner, more bread than any other European nation. In recognition, a recent law declares that no one may call himself boulanger unless his bread is mixed, kneaded, risen, shaped and baked on the premises, thus excluding the bland bread that is delivered to supermarkets pre-risen and pallid, only to be baked on the spot.

Haumonte came to fire up our centuries-old bread oven, a mystery to us when we first found it hidden in an outbuilding inhabited by hens. I had spotted a characteristic half-moon iron door, opened it, and there was the classic shallow vault and circular floor about 3 yards across. But what about the flue? I swiftly displaced the birds and set a light to some logs to find out. Flames roared out of the oven mouth like a dragon, disappearing up a chimney built outside and in front of the oven door. How on Earth could the bread be baked inside?

Haumonte showed how. He swept the ash from the flat floor of fire bricks, then carefully spread dried branches and set them alight with newspaper--no chemical starters allowed. Long, slow heating of at least three hours is best so the bricks warm evenly and retain their heat as long as possible. More logs were added until the bricks of the vault, dark at the start, seared white and clean; the soot burned off at 550 degrees. Then Haumonte raked out the remaining glowing ashes and wiped the oven floor with a quick swirl of wet rag on the end of a long pole--the first of many tours de main (turns of the hand) of the professional baker.

The bread itself, meanwhile, had been rising nicely in the warmth behind the chimney on a shelf designed for that purpose. Some 10 hours earlier, I’d watched Haumonte mix the four ingredients for classic baguette--flour, water, salt and yeast--in the form of levain, a soft, fluffy sponge of dough kept back from the previous day’s batch. He had kneaded them on the wooden work surface to a deceptively soft, elastic mass that required considerable force to manipulate--hence Haumonte’s broad shoulders.

After about five hours, when the dough had doubled in bulk, he tipped it out of its inelegant plastic bucket (modern materials do have their uses) and kneaded it again to knock out the air. The dough seemed almost to have a life of its own, and Haumonte explained that flour and yeast have a symbiotic relationship, with the yeast feeding off the sugars in the flour and the flour developing a rich, nutty flavor in contact with the enzymes in the yeast. “Good bread must rise slowly,” he insisted. “Never try to rush it.” Then he cut the dough in chunks, weighing each on an ancient brass scale to be sure it checked in at the legal 14-plus ounces.

From medieval times, bread has been strictly controlled in France, and the price of plain white bread is still subsidized today, so a baguette costs less than 5 francs, or about 80 cents. The French are adamant in preferring a white loaf (“They don’t know what’s good for them,” Haumonte says.)

It was in shaping and raising the loaves that Haumonte’s full skill came into play. He took a chunk of dough and, with gestures almost too swift to follow, he patted, folded, rolled and sealed the loaves with an under-seam called the clef (key), elongating them for baguettes and flattening, then folding them for a fendu or broken shape. Sometimes, for fun, he made a complex braid that is even on all four sides; I’ve tried to copy it but still cannot master the twists. For raising the loaves, there was no fuss with baskets or cylindrical metal molds; Haumonte simply laid the loaves on a dish towel, pleating it to separate each loaf.

After long, slow rising of at least three hours, he rolled each loaf onto the peel, the long-handled wooden shovel for placing the bread in the oven. Among his final gestures: slashing with a razor so the bread puffs evenly, or cutting and pulling open the sides for an ear of wheat, or snipping the top for hedgehog spines. It all looked so easy, but just a small slip and a loaf can be ruined. (As a young man, Haumonte’s pay would be docked for each loaf that was misshapen or had “kissed,” i.e., touched another.)

Then into the oven went the bread, with another rapid, expert jerk to deposit it directly on the hot bricks. It is the bricks, plus steam from a drenched cloth set to one side of the oven, that gives wood-baked bread its inimitable crisp, dry crust.

Baking is not only physically trying--a traditional bake house is routinely more than 100 degrees--but many bakers are forced to retire with eczema or asthma caused by constant contact with flour. The hours are crippling too. For most of his life, Haumonte has worked from midnight until noon, sleeping in the afternoons. Social life? He looked surprised. “C’est un bel metier.” (It’s a great calling.) Clearly, that is enough.

Willan is the author of “In and Out of the Kitchen in 15 Minutes or Less” (Rizzoli, 1995).

EAR OF WHEAT

1/4 cup butter

3 tablespoons honey

2 cups lukewarm water

1 tablespoon dry yeast

3 cups stone-ground whole-wheat flour

3 cups unbleached flour, plus more if needed

1 tablespoon salt

Oil

One of Robert Haumonte’s favorite loaves is shaped like an ear of wheat, perfect for breaking into individual crisp rolls. He uses plain white dough, but I like to add some whole-wheat flour for nutty flavor.

Melt butter in saucepan. Stir in honey and 1/4 cup lukewarm water. Sprinkle in yeast and let sit until dissolved, about 5 minutes.

Combine whole-wheat flour, unbleached flour and salt on work surface. Make large well in center. Add dissolved yeast and remaining 1 3/4 cups water. With fingertips, mix ingredients in well. Using pastry scraper, gradually draw in flour and mix it with liquid ingredients with other hand to form smooth dough. It should be soft and slightly sticky. If very sticky, work in more flour.

Sprinkle work surface with flour and knead dough, pushing it away from you with 1 hand and holding down 1 side with other. Peel dough from work surface, give it quarter turn and continue kneading until very smooth and elastic, 5 to 7 minutes. Add flour sparingly as dough becomes less sticky during kneading and should be soft and pliable.

Shape dough into ball. Transfer to oiled bowl and flip dough so top is oiled. Cover bowl tightly with plastic wrap. Let dough rise in warm place until doubled in bulk, 1 1/2 hours.

Turn dough onto lightly floured work surface and knead just to knock out air, 15 to 20 seconds. Cut dough with knife into 2 equal pieces. Flour hands and pat 1 piece of dough into 12x6-inch rectangle. Starting with long side, roll rectangle into cylinder. Pinch overlap to seal and form seam. With palms, roll cylinder, stretching it to 20-inch log. Flour dish towel very generously and set loaf, seam upward, at 1 side. Pleat towel along side of loaf. Shape other loaf and set it on towel against pleats. Cover loaves with dry dish towel and let rise in warm place until doubled in bulk, about 1 hour.

Roll 1 loaf onto oiled baking sheet so seam is on bottom. With large scissors, make V-shaped cut about halfway through loaf, 2 to 3 inches from one end. Pull point of dough outward from loaf. Make second cut 2 to 3 inches from first on other side of loaf. Repeat cuts and you will see the wheat ear take shape. Repeat with other loaf.

Bake loaves at 425 degrees until well browned and bottoms sound hollow when tapped with fist, 25 to 30 minutes.

2 loaves. Each of 24 servings:

133 calories; 316 mg sodium; 5 mg cholesterol; 2 grams fat; 25 grams carbohydrates; 4 grams protein; 0.39 gram fiber.

More to Read

Eat your way across L.A.

Get our weekly Tasting Notes newsletter for reviews, news and more.

You may occasionally receive promotional content from the Los Angeles Times.