Computers Help Industry Compete With Imports : U.S. Apparel Firms Go High Tech

- Share via

At the Catalina sportswear plant in Porterville, Calif., sewing-machine operators now spend most of their time sitting--much to the delight of company executives. Until the Los Angeles-based company installed new equipment, the operators had to spend hours each day hauling bundles of clothing around the plant.

The equipment, which automatically delivers garments from one sewing station to another, brings assembly-line techniques to the plant, thus freeing operators from other time-consuming tasks and boosting production by 30% to 35%.

The Catalina plant is an example of the quiet revolution taking place in the U.S. apparel industry as manufacturers go high tech to more effectively compete with imports.

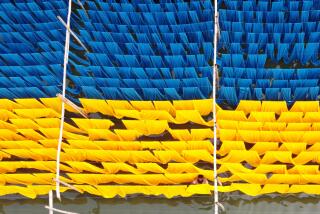

Many of the computerized systems in use today by such companies as Levi Strauss, North Face, Blue Bell and California Joy are on display at the Western Apparel Manufacturers Show at the Los Angeles Convention Center, which is sponsored by Apparel Industry magazine and closes today.

The systems help design, size and even lay out patterns on fabric. Computer-controlled cutters can follow a pattern and cut through three inches of fabric. Sewing machines can be programmed so that they automatically stop when the operator must change the position of the fabric.

Don’t Replace Operators

The systems are designed to cut costs, increase productivity and shorten the time between orders and delivery. They typically do not replace operators but are designed to save time.

Increasing mechanization and computerization are expected to help apparel makers stay competitive. They hope to beat out overseas competitors by zeroing in on the fast-moving, finicky market for trendy, fashionable clothing.

Particularly for imports from Asia, stores must place orders four to five months before delivery, a lag that often leads to oversupply and price cutting. “There are no geniuses in this fashion business who can say what’s going to sell,” says John Watte, Catalina’s vice president of operations.

Catalina has installed a system produced by Eton Machinery Inc. in two of its 10 U.S. plants. The system works likes a conveyor belt, transporting clothing on hangers from one operator to the next. A computer at each work station records the time it takes for each operator to complete a task and counts how many garments an individual works on.

With the system, Catalina can keep track of where each garment is in the factory and have better control over quality. It also cuts inventory costs, provides a neater and more orderly work environment and improves attitudes among workers, according to Watte.

Much Faster System

He says the system enables a plant to complete a garment in five hours compared to the 10 to 12 days it takes using traditional production methods. Watte said that with the new system, the company can fulfill an order within five days, whereas “we were lucky before if we could get it done in four weeks.”

The cost of modernization is hefty. Catalina invested $500,000 in two plants but Watte says the company broke even on the investment in less than a year. He says the company extensively studied the project before installing it about a year ago.

“People are afraid of the investment,” Watte says.

Allyn W. Perkins, president of Alpharetta, Ga.-based Eton, a subsidiary of a Swedish company, says, “U.S. manufacturers, especially apparel makers, are hung up on the idea of a two-year pay back. European and Japanese manufacturers are more likely to accept five years.”

But he says there is increased interest among U.S. apparel makers in new systems because “now it is a matter of survival as far as I see it.”

Steve Fineman, national sales manager for Gerber Garments Technology in South Windsor, Conn., says some of the new technology also is more affordable. Ten years ago, when his company introduced a computerized sizing and marking system for patterns, the equipment cost $250,000 to $300,000. Today, the price is down to about $85,000.

More to Read

Inside the business of entertainment

The Wide Shot brings you news, analysis and insights on everything from streaming wars to production — and what it all means for the future.

You may occasionally receive promotional content from the Los Angeles Times.